- Joined

- Dec 18, 2019

- Messages

- 6,447

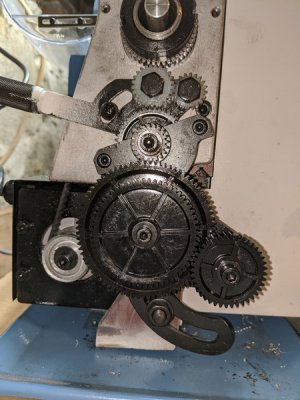

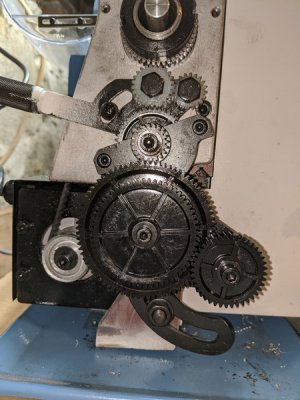

Thought I'd try some threading. I have a small rod I'd like to thread in 8-32. So, having never done this before, looked up the appropriate gear ratio and other things to do an 8-32 on my LMS 7350 high torque mini-lathe. The gear chart on gear chart says to use the following set up:

I used 20/80/60/40. (Default setup is 20/80/20/80) 60 seemed to be the only gear that would mate up with the 40. "Any gear" is kind of confusing to me. Does "any gear" mean pick whatever might properly engage the gears?

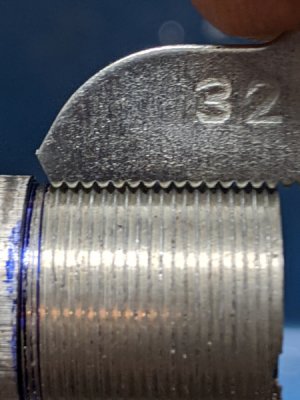

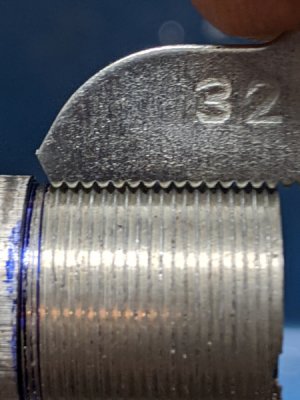

Used a piece of 1/2" aluminum for practice. It cut like 6061, but since it was unlabeled, not sure of the alloy. Used sulfur cutting oil since that is what I had. End result was not 32 TPI. The threads seem well formed, but seem to be around 21-22 threads/0.490" or 45 TPI! (OK, they aren't pretty under 60x, but due to the slow speed that I cut them at, they aren't bad.) I'm surprised about the wrong TPI. I engaged the lead screw at the same mark every time.

So what am I missing?

The mini-lathe has a 16 TPI lead screw. (And I did physically count 16 threads in an inch.) Maybe a red herring, but I never could engage the lead screw on the mark (1) of the thread dial. I could engage just before, or just after, but never on the mark. I practiced this a lot, and it seems the dial is misaligned?

I'd appreciate any help that you could give.

| A | B | C | D |

| 20 | Any gear | Any gear | 40 |

Used a piece of 1/2" aluminum for practice. It cut like 6061, but since it was unlabeled, not sure of the alloy. Used sulfur cutting oil since that is what I had. End result was not 32 TPI. The threads seem well formed, but seem to be around 21-22 threads/0.490" or 45 TPI! (OK, they aren't pretty under 60x, but due to the slow speed that I cut them at, they aren't bad.) I'm surprised about the wrong TPI. I engaged the lead screw at the same mark every time.

So what am I missing?

The mini-lathe has a 16 TPI lead screw. (And I did physically count 16 threads in an inch.) Maybe a red herring, but I never could engage the lead screw on the mark (1) of the thread dial. I could engage just before, or just after, but never on the mark. I practiced this a lot, and it seems the dial is misaligned?

I'd appreciate any help that you could give.