- Joined

- Feb 7, 2013

- Messages

- 792

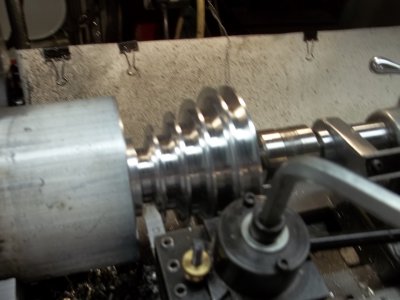

Until I can afford a different one my drill press was just to fast so I thought I would make a pulley for it and slow it down. It is a five step pulley so I had a small piece of 4 inch T6 aluminum so I chucked it up and started to work. I will post the pic's.. Ray