- Joined

- Dec 18, 2019

- Messages

- 6,464

In a separate project thread, made an 8" diameter fixture plate for my Vertex HV-6 rotary table. I drilled and tapped the plate for M6 screws.

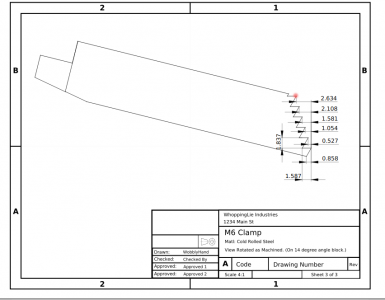

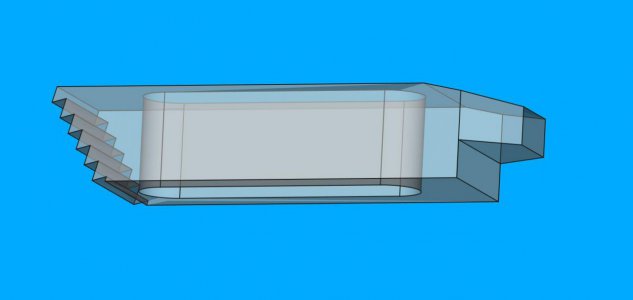

I need some clamps for the table, so I thought I would design up some and machine them. The modeling was a little trickier than expected, but I came up with a way to dimension the steps. I want to reuse my existing step blocks, so I needed to make the clamp steps consistent with the steel step blocks. Here is the drawing for the clamps. I'm not positive on the length, so I will make a prototype out of aluminum to further refine the design. There are a lot of interesting setups to make this, and plenty of places to screw up, so it will be good to do this on an easier machining material. Once the design is validated, I will make four clamps out of cold rolled steel.

This is an example of a simple part that previously, I wouldn't even thought about. Now that I have drawn this, and imagined how to machine it, I am impressed with what goes into such a part.

I need some clamps for the table, so I thought I would design up some and machine them. The modeling was a little trickier than expected, but I came up with a way to dimension the steps. I want to reuse my existing step blocks, so I needed to make the clamp steps consistent with the steel step blocks. Here is the drawing for the clamps. I'm not positive on the length, so I will make a prototype out of aluminum to further refine the design. There are a lot of interesting setups to make this, and plenty of places to screw up, so it will be good to do this on an easier machining material. Once the design is validated, I will make four clamps out of cold rolled steel.

This is an example of a simple part that previously, I wouldn't even thought about. Now that I have drawn this, and imagined how to machine it, I am impressed with what goes into such a part.