- Joined

- Jun 8, 2016

- Messages

- 603

I did it, but man what a time it was.

A couple years ago I got my shop done, 30x40 metal frame on concrete slab, metal siding and spray insulation. After getting things moved in, I had a strong hankering for a new bigger air compressor. My then current 20gal oil less was bought about '95. My desire was a 60 gallon or larger and plumbing it through the shop.

I started looking, hoping to find a good deal or a good used unit. I found several that needed repair of some sort mostly motors. Also found a couple that the motor worked but wouldn't build pressure. That started me looking for replacement parts and figuring costs.

That lead me to a website with factory replacement parts. They were pricey, and it made the overall costs not worth it. But I found one listing for an 80 gallon tank with the mounting shelf for the motor and compressor for $135. And the website offered free shipping with a purchase over $100. I called to make sure price was correct, they said yes and I ordered it.

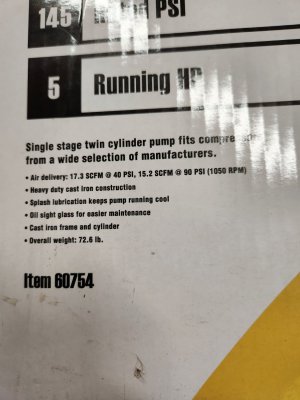

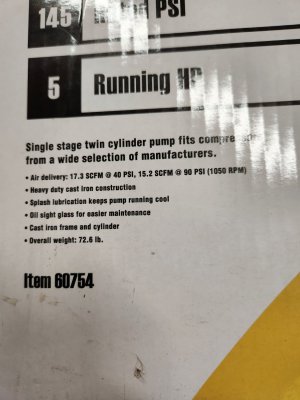

I had already looked at horrible freight pumps, and read lots of mixed reviews. But I had started with the intention of "trying to save money". I bought a 5hp compressor pump.

5hp, 15.2cfm@90psi, 17.3cfm@40psi. I take those ratings with a large grain of salt.

So now I have a tank and pump and in in this for about $300 total. Looking for a motor led me to a used Baldor 5hp farm duty for $20. Turned out to be shorted. I took it to a friend who has a motor shop and he basically traded my shorted Baldor 187 frame motor for a WEG 5hp 187frame that was "new". It was brand new with a bad capacitor. Yes he's a good friend.

Of course I had to buy all the fittings and such. Compressor Source online was awesome. I added a mag switch, large pressure dial, and hour meter. I wanted to be able to say how long this compressor was actually running when people ask me about horror freight.

I extended the intakes to help with noise. I also decided to add a moisture reducer/cooler. I decided to make the (in)famous "Franzinator".

I had read that a single Franzinator was about right for about 1-2hp compressor. Since I had the material I made a bank of 3. Each one is per the instructions I could find from Franz himself on other forums from years ago. Mine are all welded from sprinkler pipe and capped with half-round fence post caps.

After building I hooked each one up to a hydrostatic tester and tested them to 250psi. They passed holding 100psi more than the compressor is capable of.

Hardest part was plumbing. The fitting on the HF pump isn't standard. I found a video online that said it was British Straight Pipe thread. I ordered a 3/4" BST to 3/4" NPT and everything is great.

The air is plumbed from the pump cylinders to a manifold where it flows through the 3 Franzinators in parallel. Air then exits into another manifold which then feeds into the 80 gallon tank. I put the one-way check valve just before the manifold going into the Franzinators. When the motor cuts off pressure is drained off the cylinders and a short section of pipe.

The tank was black from the factory, as was the pump and motor. I added the logo and color.

All total I'm into this for about $700.

Now, I said when I started I wouldn't advise anyone to do this. That's not because I'm not happy with what I have. Rather it's because it has taken me over a year to get this done. Chasing parts, finding motors, getting repairs made.....looking back I think that spending the money upfront and getting a working unit new would have been much faster and easier.

By all accounts I've seen the HF compressor pumps either don't work from the start, or if they do work they seem to work well and for a long time. This one works, so I'm cautiously optimistic.

Hope some find it interesting. If you are a glutton for punishment or have way more time than money building might be for you.

A couple years ago I got my shop done, 30x40 metal frame on concrete slab, metal siding and spray insulation. After getting things moved in, I had a strong hankering for a new bigger air compressor. My then current 20gal oil less was bought about '95. My desire was a 60 gallon or larger and plumbing it through the shop.

I started looking, hoping to find a good deal or a good used unit. I found several that needed repair of some sort mostly motors. Also found a couple that the motor worked but wouldn't build pressure. That started me looking for replacement parts and figuring costs.

That lead me to a website with factory replacement parts. They were pricey, and it made the overall costs not worth it. But I found one listing for an 80 gallon tank with the mounting shelf for the motor and compressor for $135. And the website offered free shipping with a purchase over $100. I called to make sure price was correct, they said yes and I ordered it.

I had already looked at horrible freight pumps, and read lots of mixed reviews. But I had started with the intention of "trying to save money". I bought a 5hp compressor pump.

5hp, 15.2cfm@90psi, 17.3cfm@40psi. I take those ratings with a large grain of salt.

So now I have a tank and pump and in in this for about $300 total. Looking for a motor led me to a used Baldor 5hp farm duty for $20. Turned out to be shorted. I took it to a friend who has a motor shop and he basically traded my shorted Baldor 187 frame motor for a WEG 5hp 187frame that was "new". It was brand new with a bad capacitor. Yes he's a good friend.

Of course I had to buy all the fittings and such. Compressor Source online was awesome. I added a mag switch, large pressure dial, and hour meter. I wanted to be able to say how long this compressor was actually running when people ask me about horror freight.

I extended the intakes to help with noise. I also decided to add a moisture reducer/cooler. I decided to make the (in)famous "Franzinator".

I had read that a single Franzinator was about right for about 1-2hp compressor. Since I had the material I made a bank of 3. Each one is per the instructions I could find from Franz himself on other forums from years ago. Mine are all welded from sprinkler pipe and capped with half-round fence post caps.

After building I hooked each one up to a hydrostatic tester and tested them to 250psi. They passed holding 100psi more than the compressor is capable of.

Hardest part was plumbing. The fitting on the HF pump isn't standard. I found a video online that said it was British Straight Pipe thread. I ordered a 3/4" BST to 3/4" NPT and everything is great.

The air is plumbed from the pump cylinders to a manifold where it flows through the 3 Franzinators in parallel. Air then exits into another manifold which then feeds into the 80 gallon tank. I put the one-way check valve just before the manifold going into the Franzinators. When the motor cuts off pressure is drained off the cylinders and a short section of pipe.

The tank was black from the factory, as was the pump and motor. I added the logo and color.

All total I'm into this for about $700.

Now, I said when I started I wouldn't advise anyone to do this. That's not because I'm not happy with what I have. Rather it's because it has taken me over a year to get this done. Chasing parts, finding motors, getting repairs made.....looking back I think that spending the money upfront and getting a working unit new would have been much faster and easier.

By all accounts I've seen the HF compressor pumps either don't work from the start, or if they do work they seem to work well and for a long time. This one works, so I'm cautiously optimistic.

Hope some find it interesting. If you are a glutton for punishment or have way more time than money building might be for you.