picked this up a few days ago for 100.00. has some issues. worst is the arc or shame on the table. morons. the motor has to be spun by the pulley to start. I have a box-O-capacitors so hopefully that's it. last but not least, runout in the spindle. hoping it's just bearing. we will see.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South Bend drill press

- Thread starter yota

- Start date

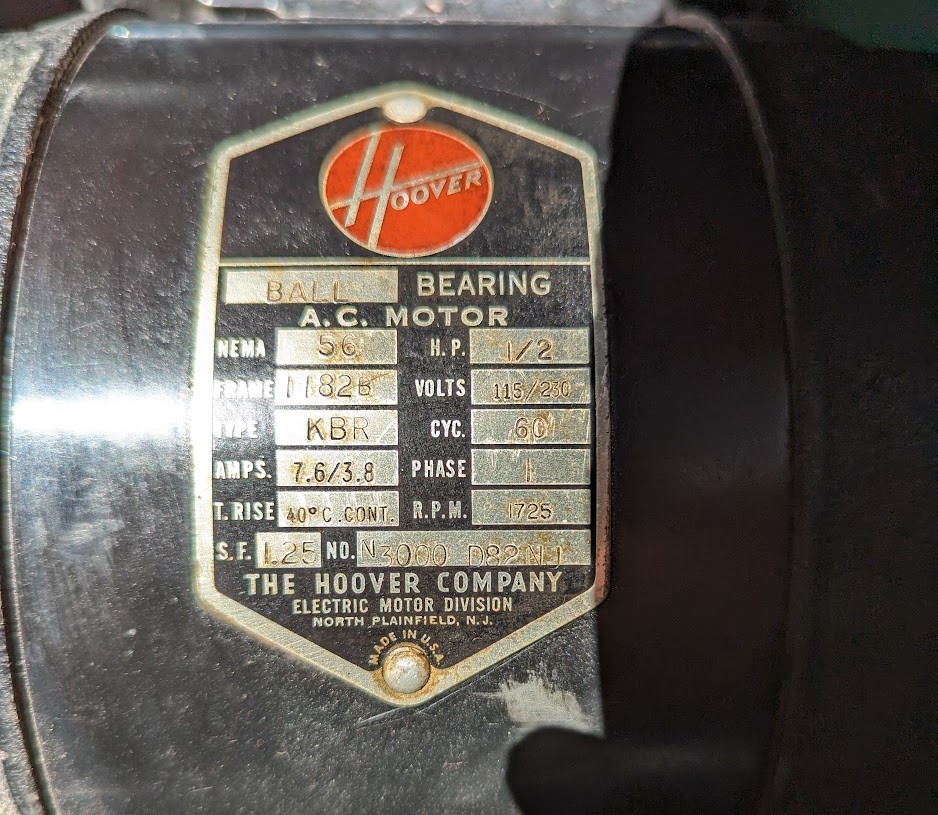

anyone ever seen a drill press with a Hoover motor before? likely not stock. all the specs on the motor are good for this drill press though.

need to figure out year of production. I read that SB announced these as a new item for production in 1948 and I think they were made into the 60's maybe. first one I've ever seen live.

need to figure out year of production. I read that SB announced these as a new item for production in 1948 and I think they were made into the 60's maybe. first one I've ever seen live.

- Joined

- Apr 14, 2014

- Messages

- 3,156

I have a Hoover motor on a Sanford MG surface grinder. As far as I know it is the original. The tag refers to it as an "industrial motor with sealed deep groove ball bearings". Standard duty Hoover motors of that era came with plain bearings (bushings) rather than ball bearings. Many manufacturers in the 40's and 50's sold their machines with or without a motor. They specified what type should be used, but let the customer decide if they wanted to order one with the machine or supply their own.

I was reading after I posted this and learned that Walker Turner used Hoover motors on many of their drill presses and other machinery, as did some other companies. no mention of South Bend but you are correct about most of the machinery companies selling with or without motors. who could know after all this time. it's a quiet little motor once I get it spun up. thanks, projectnut.

- Joined

- Mar 26, 2014

- Messages

- 1,499

Nice drill press!

I have a cast iron box table with dozens of oopsies. Really annoyed me when I got it. I was always going to braze them up but never got around to it. Probably cost a fortune in brazing rod and acetylene. Only bothers me now when I look at it. I keep it covered with a large machine vice.

Martin

I have a cast iron box table with dozens of oopsies. Really annoyed me when I got it. I was always going to braze them up but never got around to it. Probably cost a fortune in brazing rod and acetylene. Only bothers me now when I look at it. I keep it covered with a large machine vice.

Martin

- Joined

- Mar 26, 2018

- Messages

- 8,407

Great find!

I couldn't help myself on this one. I would take it apart, replace the quill bearings, polish the column on the lathe, remove the rust, clean and repaint (a gloss industrial grey, a bit darker).

She is a beauty!!!

I couldn't help myself on this one. I would take it apart, replace the quill bearings, polish the column on the lathe, remove the rust, clean and repaint (a gloss industrial grey, a bit darker).

She is a beauty!!!

true. thanks.JB Weld is an option also.

Martin

oh, it will be coming apart. there are also bearings in the front pulley that need to be checked. this has def been re-painted at least once, they used screws in the data plate when they put it back. from what I've googled, the early ones were a light green. here's the last drill press I re-did.Great find!

I couldn't help myself on this one. I would take it apart, replace the quill bearings, polish the column on the lathe, remove the rust, clean and repaint (a gloss industrial grey, a bit darker).

She is a beauty!!!