- Joined

- Aug 2, 2020

- Messages

- 562

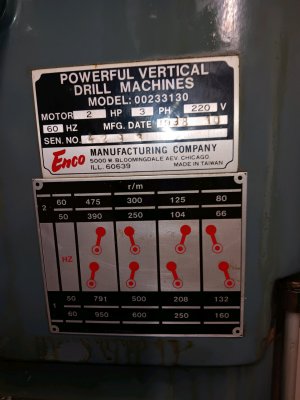

I bought this drill last summer.

It is an exact copy of an Arboga E 830 that was made in Sweden till about in the 1980s.

The base was cracked - must have been dropped - so I got it fairly cheap.

I spent most of a day trying to weld the cast iron base but it continued to crack again. So, knowing I would never trust it I decided to make a new base for it.

My 87 yo pal Kenny has a nephew that could laser cut this piece of 1/2" plate for the top and we got that done on Tuesday.

I have some 1/2×2 1/2 hot rolled that I will use to make the sides and some 1/2×2 and an 8×8" square piece of 1/2" to weld underneath for gussets and where the column will get bolted on.

It wont have the slots like original but I will drill and tap two rows of threaded holes for bolting things down.

This will go to Kenny's shop for as long as he needs it.

This one has the foot pedal for instant reversing. It is a great drill. Too bad about the cracked base but I wouldn't have got it otherwise.

I don't have heat in that area of my shop so will work on this on milder days. But I am looking forward to burning some 5/32" 7018 rod for the first time in a few years.

It is an exact copy of an Arboga E 830 that was made in Sweden till about in the 1980s.

The base was cracked - must have been dropped - so I got it fairly cheap.

I spent most of a day trying to weld the cast iron base but it continued to crack again. So, knowing I would never trust it I decided to make a new base for it.

My 87 yo pal Kenny has a nephew that could laser cut this piece of 1/2" plate for the top and we got that done on Tuesday.

I have some 1/2×2 1/2 hot rolled that I will use to make the sides and some 1/2×2 and an 8×8" square piece of 1/2" to weld underneath for gussets and where the column will get bolted on.

It wont have the slots like original but I will drill and tap two rows of threaded holes for bolting things down.

This will go to Kenny's shop for as long as he needs it.

This one has the foot pedal for instant reversing. It is a great drill. Too bad about the cracked base but I wouldn't have got it otherwise.

I don't have heat in that area of my shop so will work on this on milder days. But I am looking forward to burning some 5/32" 7018 rod for the first time in a few years.