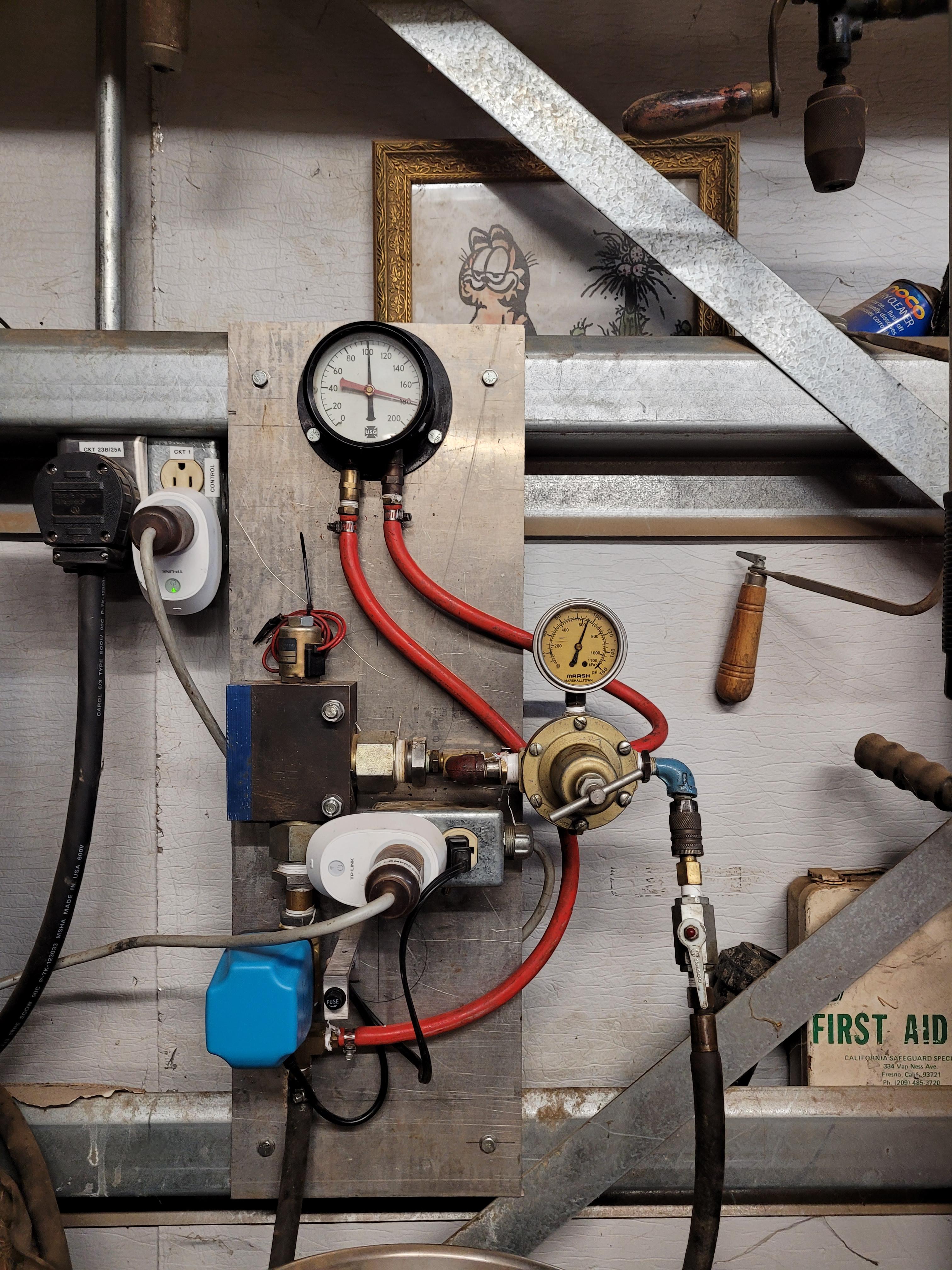

So .... I have 30 gallon compressor that I use in the shop.  The thing is I only need it a couple times each time I'm in the garage so I don't need it on all the time (and my setup is a little leaky) but I always forget to turn it off hen I'm done.

The thing is I only need it a couple times each time I'm in the garage so I don't need it on all the time (and my setup is a little leaky) but I always forget to turn it off hen I'm done.  Sooooo... I'm looking for a special switch but I don't know what it's called. Here's what I'm looking for: I press the button to turn the compressor on, the compressor runs until it shuts off at pressure, the switch cuts power to the compressor so it won't come on again until I press the button again.

Sooooo... I'm looking for a special switch but I don't know what it's called. Here's what I'm looking for: I press the button to turn the compressor on, the compressor runs until it shuts off at pressure, the switch cuts power to the compressor so it won't come on again until I press the button again.

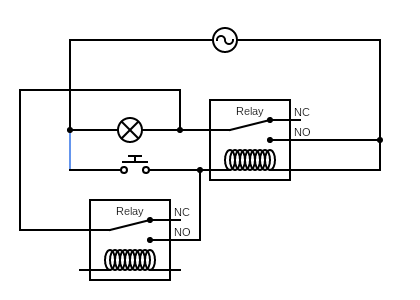

A bonus would be if there was a 'lock' mode that would keep it on until the lock is disabled (for marathon sessions) My compressor is 110v. Ideally this would be 1 piece drop in. I know I could do it with a push button and a relay but I like simple solutions...

The thing is I only need it a couple times each time I'm in the garage so I don't need it on all the time (and my setup is a little leaky) but I always forget to turn it off hen I'm done.

The thing is I only need it a couple times each time I'm in the garage so I don't need it on all the time (and my setup is a little leaky) but I always forget to turn it off hen I'm done. A bonus would be if there was a 'lock' mode that would keep it on until the lock is disabled (for marathon sessions) My compressor is 110v. Ideally this would be 1 piece drop in. I know I could do it with a push button and a relay but I like simple solutions...