- Joined

- Aug 7, 2018

- Messages

- 668

Hi Izzy,

OK ! Lets stop at this point and do nothing else!

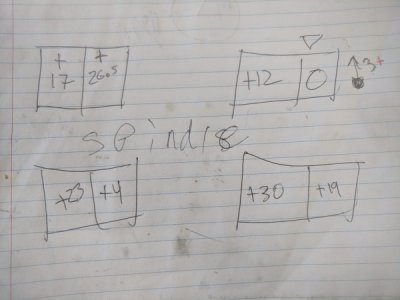

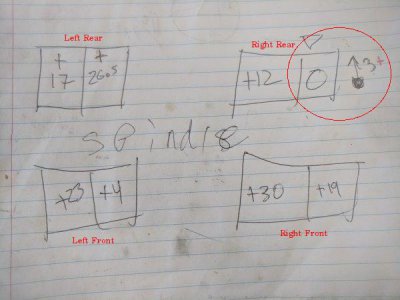

I want to make sure that we are both talking the same language. Refer to my picture.

If you remove the headstock and place it on your mill table, making sure that everything is clean and there is no rock. No need to clamp anything down for the moment. Using a dial gauge in the mill spindle, measure the hight differences on each of the pillar surfaces, at each end of each of the four and in the middle where the bolt hole is.

I am not interested in the hight from the base of the headstock casting. I'm just wanting to find a datum point.

So if the front left, left side is considered zero. What is the middle and right edges. Plus 1 thou, minus 1 thou or nothing.

Without changing the gauge hight, compare the other pillars.

Do a sketch and write the figures down.

OK ! Lets stop at this point and do nothing else!

I want to make sure that we are both talking the same language. Refer to my picture.

If you remove the headstock and place it on your mill table, making sure that everything is clean and there is no rock. No need to clamp anything down for the moment. Using a dial gauge in the mill spindle, measure the hight differences on each of the pillar surfaces, at each end of each of the four and in the middle where the bolt hole is.

I am not interested in the hight from the base of the headstock casting. I'm just wanting to find a datum point.

So if the front left, left side is considered zero. What is the middle and right edges. Plus 1 thou, minus 1 thou or nothing.

Without changing the gauge hight, compare the other pillars.

Do a sketch and write the figures down.