- Joined

- Jan 20, 2016

- Messages

- 1,011

The motor for the spindle of my Syil X4+ CNC mill quit last night. I'm not much with electronics and am not sure how to trouble shoot this. I'm a mechanic, not an electrician.

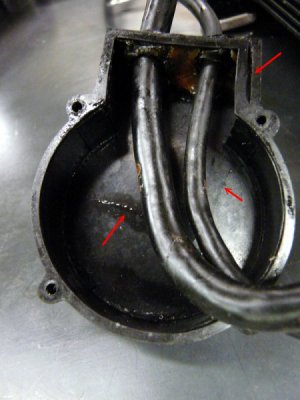

The motor will make a revolution or 2 then rattles something awful and quits. I can hit "spindle stop" and "spindle start" and it does the same thing again. I forgot to try it in the reverse direction - I'll go try that in a bit. It sounds like a bearing is out but the motor turns easy by hand without any roughness or binding.

I've attached a short video so you can hear the rattling sound.

Any knowledgeable help would be greatly appreciated.

P1040039.MOV

The motor will make a revolution or 2 then rattles something awful and quits. I can hit "spindle stop" and "spindle start" and it does the same thing again. I forgot to try it in the reverse direction - I'll go try that in a bit. It sounds like a bearing is out but the motor turns easy by hand without any roughness or binding.

I've attached a short video so you can hear the rattling sound.

Any knowledgeable help would be greatly appreciated.

P1040039.MOV