Hello All,

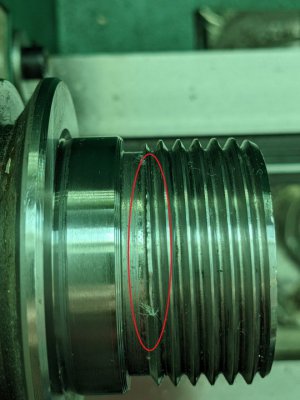

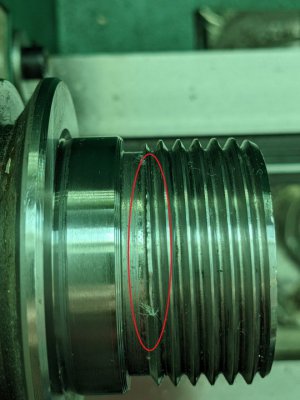

I recently took the chuck off of my lathe for just the second time and this time I noticed that there is some damage on the spindle threads.

There are a few dents and dings on some of the threads and there is a section of thread about half an inch long that looks a little ragged. I have a Grizzly G0602 and I'm thinking that since on this machine the chuck registers against a face behind the threads that this might not be too big of a deal.

I don't really know what I'm talking about though, so I could be wrong.

I'm an industrial repair tech by trade, so I'm confident that I could file the threads a little to remove any high spots without causing more damage, but will this cause run out in the chuck? Should I just leave it alone? I've heard that spindle damage is not great for lathes...

Also, the face that the chuck seats against is fine and the taper on the inside of the spindle is fine.

Thanks!

-Rick

I recently took the chuck off of my lathe for just the second time and this time I noticed that there is some damage on the spindle threads.

There are a few dents and dings on some of the threads and there is a section of thread about half an inch long that looks a little ragged. I have a Grizzly G0602 and I'm thinking that since on this machine the chuck registers against a face behind the threads that this might not be too big of a deal.

I don't really know what I'm talking about though, so I could be wrong.

I'm an industrial repair tech by trade, so I'm confident that I could file the threads a little to remove any high spots without causing more damage, but will this cause run out in the chuck? Should I just leave it alone? I've heard that spindle damage is not great for lathes...

Also, the face that the chuck seats against is fine and the taper on the inside of the spindle is fine.

Thanks!

-Rick