Hello...

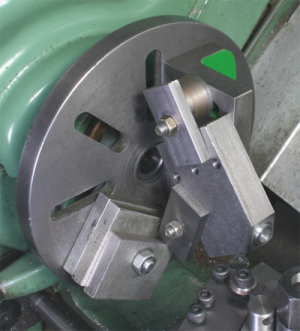

I want to make Norman style QCTP. But I hit into trouble as my mini lathe had only 3 yaw chuck. So how to put that 50mm x 50mm rectangle in chuck to bore 25mm hole?!?

Probably easy task for one that know... But I don't so it's hard for me...

Slavko

I want to make Norman style QCTP. But I hit into trouble as my mini lathe had only 3 yaw chuck. So how to put that 50mm x 50mm rectangle in chuck to bore 25mm hole?!?

Probably easy task for one that know... But I don't so it's hard for me...

Slavko