Started this a while ago, keeps getting out on the back burner due to shop problems and break downs. Still working on my lathe DC drive system that failed...

It's based on Stefan Gotteswinter's project. Did a bunch more mill work last night on the top slide piece.

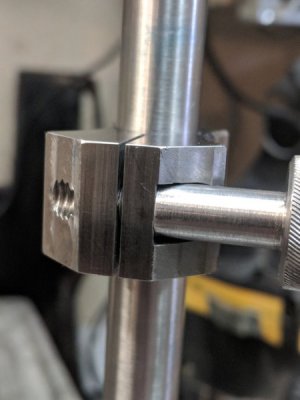

And my progress so far.

To use as a surface guage, I can just spin the top slide around to the back and extend the DTI off the back for about 4" of reach. Not a huge amount of surface covered, but more than I have right now, which is nothing, and my surface plate is small.

I figured with the addition of the surface grinder, and my hopes of making lapping plates, I really need a way to measure squareness and surfaces.

It would be nice to afford a nice reference standard tho. I may just have to rely on comparative squaring. Checking both sides of something and splitting the difference.

It's based on Stefan Gotteswinter's project. Did a bunch more mill work last night on the top slide piece.

And my progress so far.

To use as a surface guage, I can just spin the top slide around to the back and extend the DTI off the back for about 4" of reach. Not a huge amount of surface covered, but more than I have right now, which is nothing, and my surface plate is small.

I figured with the addition of the surface grinder, and my hopes of making lapping plates, I really need a way to measure squareness and surfaces.

It would be nice to afford a nice reference standard tho. I may just have to rely on comparative squaring. Checking both sides of something and splitting the difference.

Last edited by a moderator: