- Joined

- Jul 15, 2020

- Messages

- 421

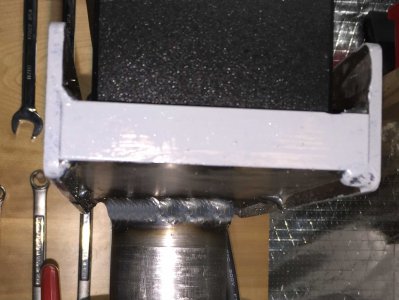

I just purchased a 1 h.p. 11 amp 8" bench grinder, and I'm trying to decide what to mount it on. I have it temporarily sitting on an 18" x 24" work stand with locking casters. I also have a 40 lb. 19" diameter drill press base with a 2 3/4" x 31" column in its center. I am considering welding a piece of 1/2" plate at the top to accommodate the grinder.

If I mount it on the drill press column, I can free up the work stand, which I use frequently for other purposes. It would also take up slightly less floor space. However, I would give up the shelf underneath, which might be used for extra wheels, and jigs, and other items. It would also become stationary. One of the pics shows a photoshop likeness of what it would look like on the column.

What would you guys do?

If I mount it on the drill press column, I can free up the work stand, which I use frequently for other purposes. It would also take up slightly less floor space. However, I would give up the shelf underneath, which might be used for extra wheels, and jigs, and other items. It would also become stationary. One of the pics shows a photoshop likeness of what it would look like on the column.

What would you guys do?