-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starrett Level Help

- Thread starter sped35

- Start date

- Joined

- Jan 7, 2013

- Messages

- 485

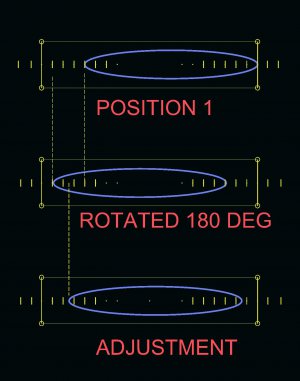

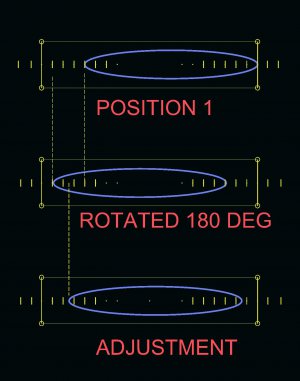

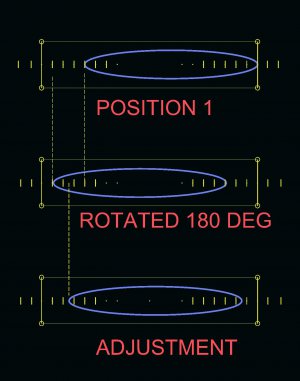

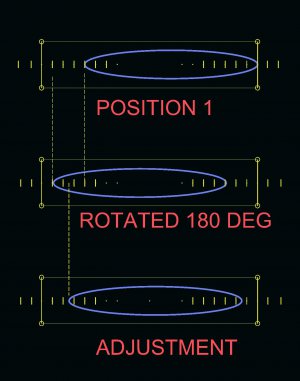

Even after having my Starrett 18-inch rebuilt I needed to reset the vile. It is relatively easy to do. You flip it end for end and adjust until the readings on the vile are the same. Level does not need to be perfectly level to make the adjustments, just make sure the reading is the same in both directions. Even temperature change can affect the readings.

Last edited:

For jmh8743

Hi Mike,

(Now adjustment is easy. Let me know if you want to know how AND you do not need a perfectly level surface.)

I am interested in knowing how, I have an old Lufkin #58 12" long. Especially the part about it doesn't have to be perfectly level.

Thanks,

RWW

Hi Mike,

(Now adjustment is easy. Let me know if you want to know how AND you do not need a perfectly level surface.)

I am interested in knowing how, I have an old Lufkin #58 12" long. Especially the part about it doesn't have to be perfectly level.

Thanks,

RWW

- Joined

- Oct 17, 2012

- Messages

- 126

RWW,

1. find a flat surface, mill table, vice, etc the length of your level. I use my band saw table. A circular saw table OK.

2. set the left end on your left hand. This end is not adjusted, the one with the cross vial.

3. Read the left end of the bubble. The surface must be level enough to be able to read one of the graduations, but flat.

4. Remember the location measured from the hash mark and the direction.

5. Rotate the level 180^. (Now the jams nuts are on the left side. First iteration)

6. slightly loosen the vial case screw on the right.

7. loosen the jam nut on top, now on the left hand.

8. adjust the bottom nut until the bubble takes out HALF the difference. hand tighten jam.

9. RETURN TO 5

Finally, there will be no adjustment.

when satisfied, tighten jam and case screw. You will have to do this several times a year.

Lastly, insert a thick card stock under one end, mine measures .007", and tell me how many graduations and partial graduations this moves the bubble.

Tell me the thickness of your stock. The length of your vial tells me this will be a great level. Now it is adjusted to read "plumb" as it is called.

Mike

Remlap AL

1. find a flat surface, mill table, vice, etc the length of your level. I use my band saw table. A circular saw table OK.

2. set the left end on your left hand. This end is not adjusted, the one with the cross vial.

3. Read the left end of the bubble. The surface must be level enough to be able to read one of the graduations, but flat.

4. Remember the location measured from the hash mark and the direction.

5. Rotate the level 180^. (Now the jams nuts are on the left side. First iteration)

6. slightly loosen the vial case screw on the right.

7. loosen the jam nut on top, now on the left hand.

8. adjust the bottom nut until the bubble takes out HALF the difference. hand tighten jam.

9. RETURN TO 5

Finally, there will be no adjustment.

when satisfied, tighten jam and case screw. You will have to do this several times a year.

Lastly, insert a thick card stock under one end, mine measures .007", and tell me how many graduations and partial graduations this moves the bubble.

Tell me the thickness of your stock. The length of your vial tells me this will be a great level. Now it is adjusted to read "plumb" as it is called.

Mike

Remlap AL