- Joined

- Apr 12, 2013

- Messages

- 562

Putting this here instead of projects since it is a rifle. Ongoing project, I'll update as I have progress. I may be asking too much but I think I am going to need some help with this!

For my 3rd rebarrel I chose a mid 90's Winchester M70 Classic Featherweight in 243Win. It has never been very accurate and the bore is full of machining marks. I bought a SS Douglas #2 profile barrel blank in 1:8 twist 6mm bore. I have a PTG 243Win reamer (used for one barrel previously) and both go and no-go gages.

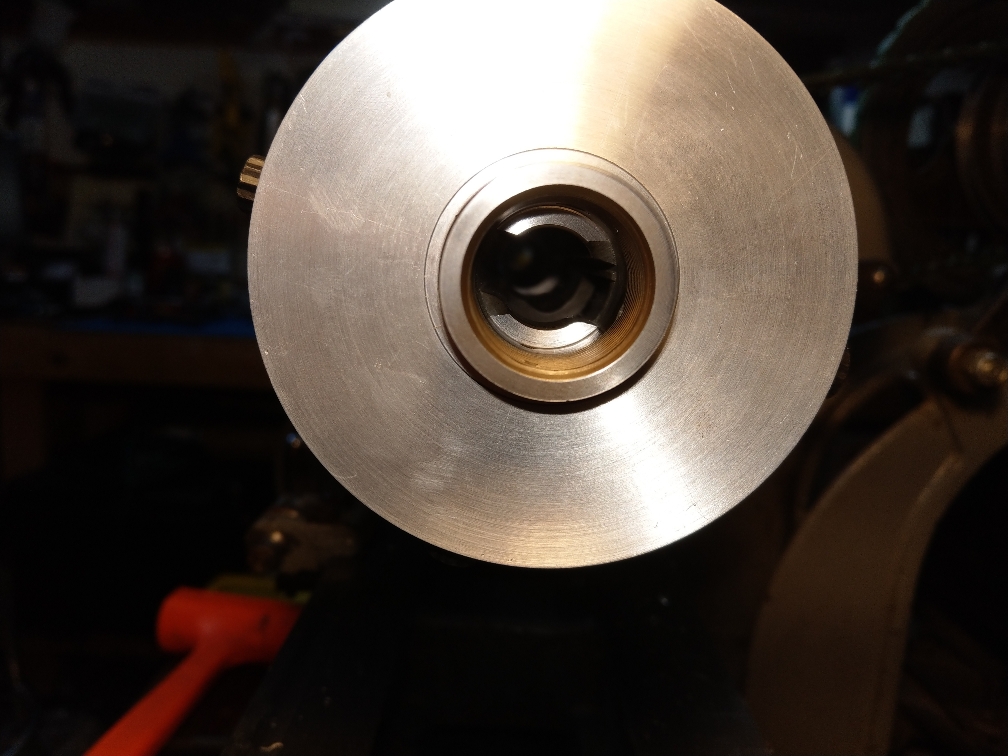

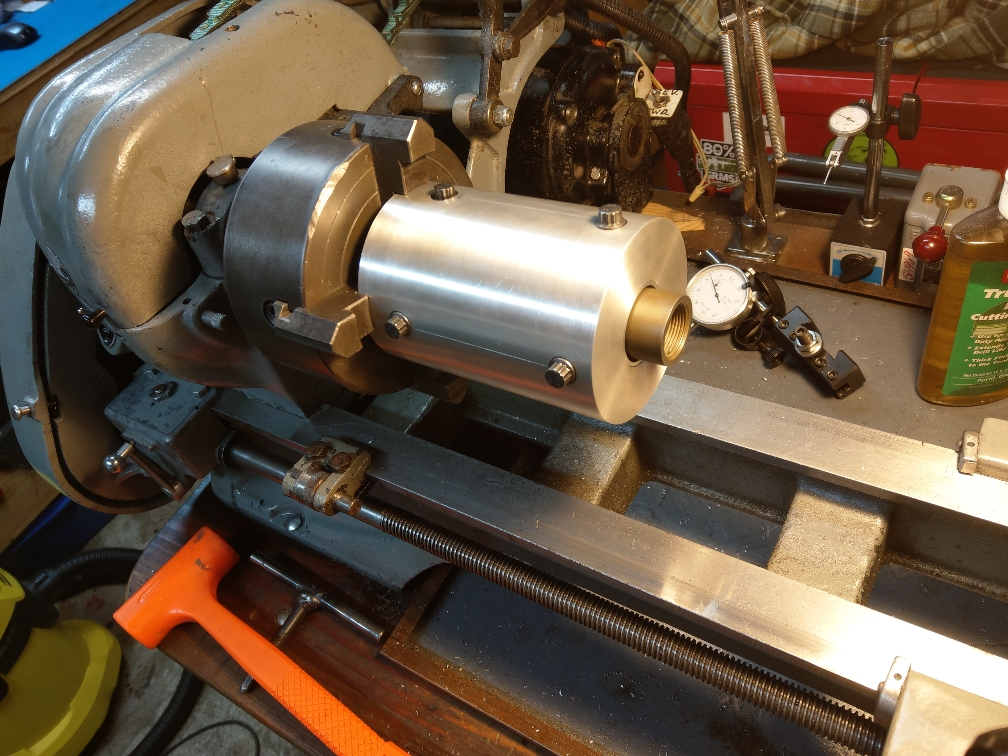

I cut a barrel bushing and after a lot of effort got the barrel off.

One look at the action face and I decided this can't be 'just' a rebarrel. This is ugly. Please let me know if I miss anything:

Rough action face, poor barrel to action mating surface contact

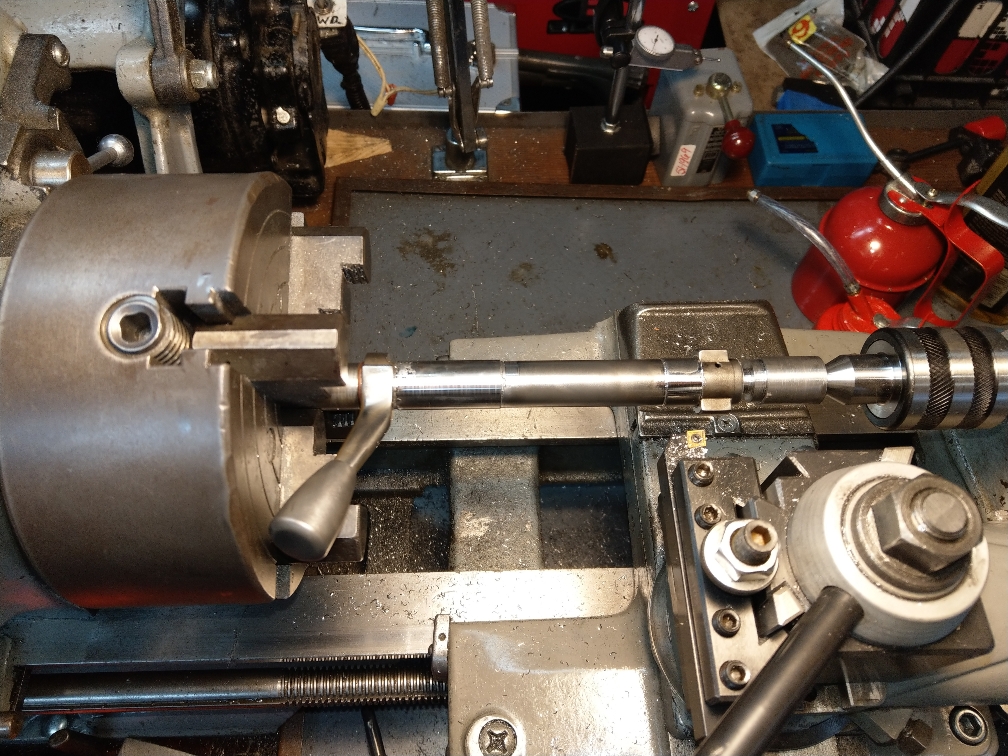

Lugs not bearing evenly

So now I am going to try and build a cat head to true the action. This project just got a lot more complex. Is truing the threads, action face, and lugs enough for an intended light but accurate (call it 400 yard max for pronghorn hunts) hunting rifle?

For my 3rd rebarrel I chose a mid 90's Winchester M70 Classic Featherweight in 243Win. It has never been very accurate and the bore is full of machining marks. I bought a SS Douglas #2 profile barrel blank in 1:8 twist 6mm bore. I have a PTG 243Win reamer (used for one barrel previously) and both go and no-go gages.

I cut a barrel bushing and after a lot of effort got the barrel off.

One look at the action face and I decided this can't be 'just' a rebarrel. This is ugly. Please let me know if I miss anything:

Rough action face, poor barrel to action mating surface contact

Lugs not bearing evenly

So now I am going to try and build a cat head to true the action. This project just got a lot more complex. Is truing the threads, action face, and lugs enough for an intended light but accurate (call it 400 yard max for pronghorn hunts) hunting rifle?