- Joined

- Oct 14, 2014

- Messages

- 1,970

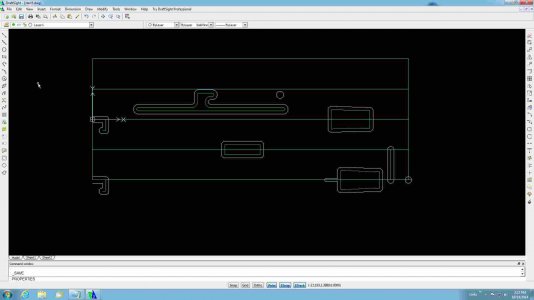

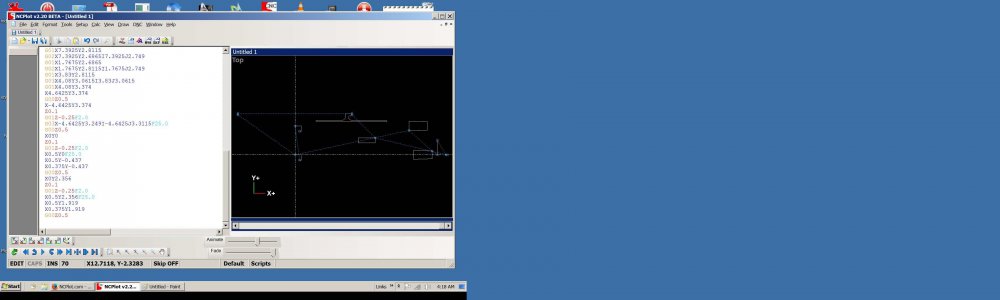

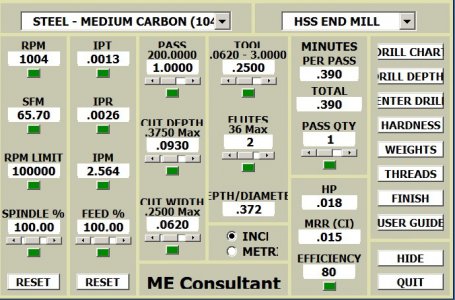

This is my Sten receiver tube project. For those not aware, you can buy pieces of old cut up military weapons and rebuild them into semi-auto rifles. In nearly all cases, the receiver is cut up and destroyed on these parts kits. Here's info on the Sten: http://en.wikipedia.org/wiki/Sten. BUT FIRST, you need the project to do the project. I just finished installing a servo motor to drive my index head. Here's everything mounted on the table: