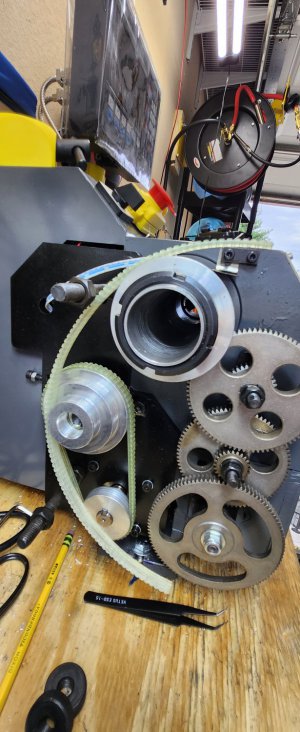

Just got a new lathe it's basically a WM210 except with the 1.5 in spindle bore in MT5 taper. Problem I've got is I've got to change the speed from low to high and I can't for the life of me figure out how to loosen the tension on the belt to get the belt to move between the two sets of pulleys. I've managed to break one belt already and figure it I'd ask for help from the experts.

Would really appreciate it if someone could point out what I should be loosening to get the tension down. I've loosened and even removed the bolt with the holding nut under and perpendicular to the variable speed pulley that's missing the belt now but it didn't seem to loosen it at all.

Thanks for all the help in advance.

Would really appreciate it if someone could point out what I should be loosening to get the tension down. I've loosened and even removed the bolt with the holding nut under and perpendicular to the variable speed pulley that's missing the belt now but it didn't seem to loosen it at all.

Thanks for all the help in advance.