Low, mid and high, huh? That would appear to match the 3 step pulley, but it's hard to see how that can work. At this point I would suggest: RTFM. If you don't have a manual I bet the internet will produce something.

A bit of online searching on my part suggests your machine is made/sold by Vevor. One youtube video I found was not particularly positive in terms of the build quality, but that's not all that unusual for inexpensive lathes. One potentially valuable insight I garnered from the video was regarding the direction and speed selectors. It apparently is all to easy to turn them too far, which can result in damage to the scarce-as-hen's-teeth gears in there. Apparently Vevor doesn't sell replacements for them......

The comments about build quality suggest that perhaps you are NOT doing anything wrong, maybe the lathe is at fault. Caution: learning experience ahead.

The spindle bore ID is a nice upgrade from the 7x series of lathes from Sieg and Real Bull so I hope you can solve the issues you encounter

The large spindle bore is what made me pick this one. I didn’t buy it from Vevor because they were out of stock but this looks like it came from the same factory.

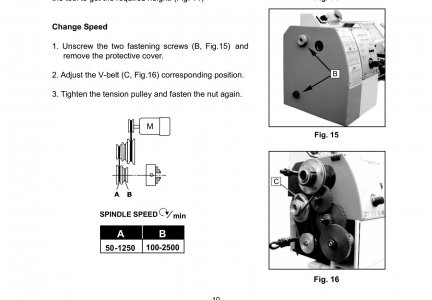

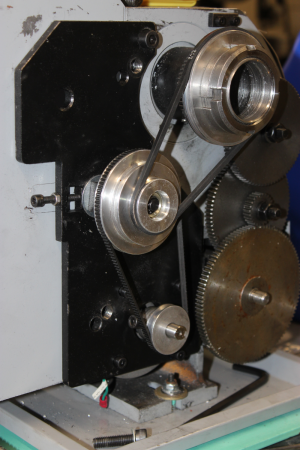

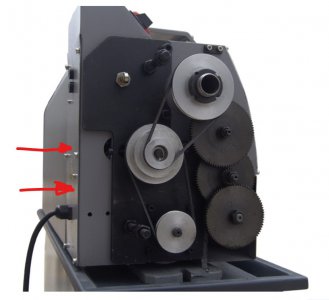

The manual it came with looks like they just copied it from the manual for similar but not identical models. Found the original file they must have copied online and it has pretty useless instructions on changing the belt. It refers to a tensioning pulley. Not sure if that’s the same as the 3 belt pulley or if it’s not there.

Attached the picture in case someone has better reading comprehension skills than me.