- Joined

- Dec 27, 2014

- Messages

- 4,060

My Clausing/Atlas 6 x 24 Mark II lathe has a Westinghouse 1/3 horse, 115 Volt 6.3 Amp motor. Its ID tag says "For CW Rot., Interchange Red and Black" I understand that this means I can reverse the motor by switching these two connectors. The off/on switch is currently a small toggle switch, commonly noted as 15 amp.

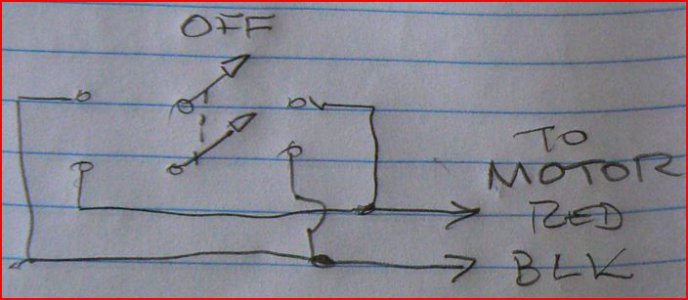

My question is....Can I use a similar double pole double throw (center off) switch to reverse the motor? If so, what size wire would be best for these connections?

Thanks.

My question is....Can I use a similar double pole double throw (center off) switch to reverse the motor? If so, what size wire would be best for these connections?

Thanks.