Warning, ....I am about to show how little I know...

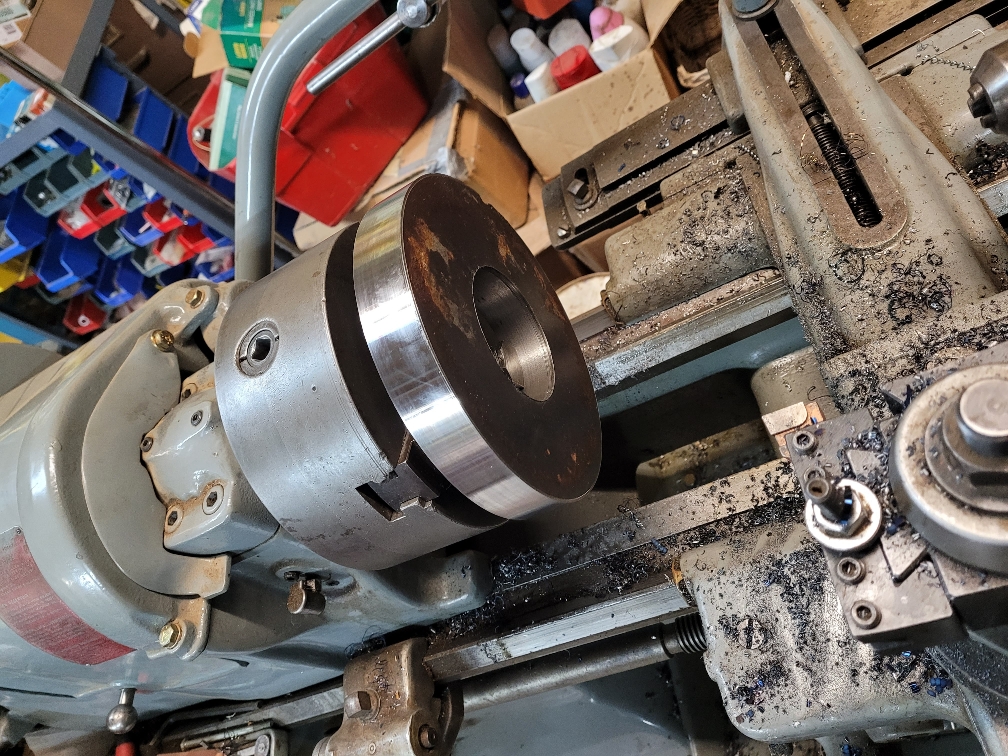

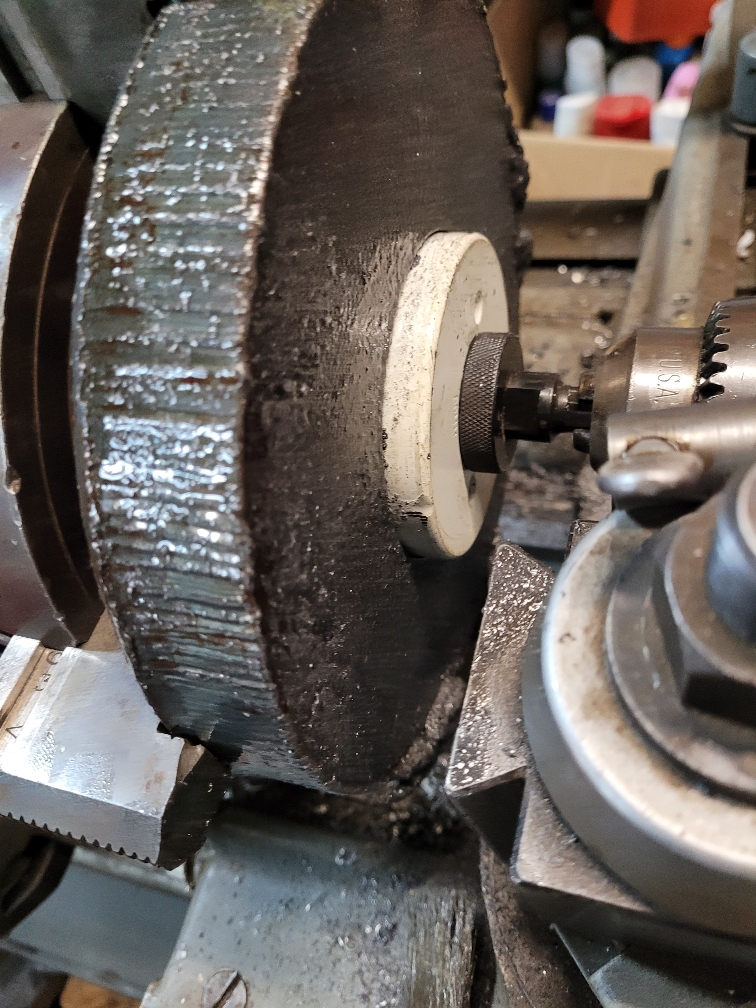

When I first received my PM1236 last April, I noted that the tail stock tapers had the flanges but this caused them to reduce the amount of quill travel. Not knowing what they added to the taper function, I cut them off, including the one for the drill chuck that I had. As long as I have had lathes, I have learned to not be too aggressive with drilling as it might cause the taper to spin in the tail stock quill. But then watching a video recently, a comment was made that the flange prevents the tailstock mounted drill chuck from spinning....DOH! So figuring a new one is a week away with shipping probably, I figured I would weld a new one on. Not a big deal but then installing it, I found it does nothing to prevent the chuck from spinning, should it become loose.

So is the PM1236 setup to accommodate a tanged MT3? It came with them but when I looked into the taper hole, I saw no place for it to lock into, and my new modified one did not lock or catch when I put it in lightly so as not to engage the taper. Or is it still a matter of light drilling operations when using the tail stock? I looked at the parts diagram but it did not give me any more info.

A second question, does this lathe normally come with a wrench to remove the chucks? The 3 jaw wrench fits but is too short as is the 4 jaw one, albeit longer. They can work. I ended up using a ratchet extension. Someone said a good project and this is true so no big deal but wondering what you all have done. Did you make a "chuck change tool" or do you just use a ratchet extension?

Please don't take these as complaints. I am loving the lathe, to the point of maybe buying a mill from PM. I am just wondering what others are doing, and, of course, suggestions on the drill chuck spinning in the tail stock when no tang is present.

Thanks

Shawn

When I first received my PM1236 last April, I noted that the tail stock tapers had the flanges but this caused them to reduce the amount of quill travel. Not knowing what they added to the taper function, I cut them off, including the one for the drill chuck that I had. As long as I have had lathes, I have learned to not be too aggressive with drilling as it might cause the taper to spin in the tail stock quill. But then watching a video recently, a comment was made that the flange prevents the tailstock mounted drill chuck from spinning....DOH! So figuring a new one is a week away with shipping probably, I figured I would weld a new one on. Not a big deal but then installing it, I found it does nothing to prevent the chuck from spinning, should it become loose.

So is the PM1236 setup to accommodate a tanged MT3? It came with them but when I looked into the taper hole, I saw no place for it to lock into, and my new modified one did not lock or catch when I put it in lightly so as not to engage the taper. Or is it still a matter of light drilling operations when using the tail stock? I looked at the parts diagram but it did not give me any more info.

A second question, does this lathe normally come with a wrench to remove the chucks? The 3 jaw wrench fits but is too short as is the 4 jaw one, albeit longer. They can work. I ended up using a ratchet extension. Someone said a good project and this is true so no big deal but wondering what you all have done. Did you make a "chuck change tool" or do you just use a ratchet extension?

Please don't take these as complaints. I am loving the lathe, to the point of maybe buying a mill from PM. I am just wondering what others are doing, and, of course, suggestions on the drill chuck spinning in the tail stock when no tang is present.

Thanks

Shawn