- Joined

- Oct 6, 2021

- Messages

- 9

Hello all,

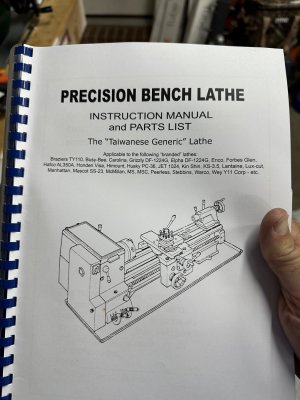

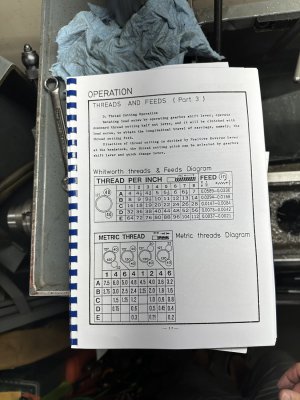

A few years ago I acquired this lathe from my uncle who was unfortunately unable to use it due to failing health. It’s served me well and I very much enjoy my new hobby and I’m happy it’s still in the family. My latest project requires me to cut a 1.5 metric thread. It’s my understanding this is a “generic Taiwanese import lathe” circa the 1980’s with similar designs that were sold under many labels. The lathe didn’t come with a manual, however, I was able to source a generic one size fits all manual. According to it, this having an imperial lead screw, I’ll need a couple of change gears to be able to cut metric threads. Unfortunately, they were not included when I acquired the lathe. I’ve read some threads where folks with similar lathes were able to source some parts from Grizzly as they apparently sold a version of this lathe, the G9249. On Grizzly’s website they offer 30t, 32t, and 46t change gears but unfortunately they are all back ordered.

According to the manual I have, I’ll need the 32t gear to cut 1.5 metric threads. I would like to have all three for future projects as well. I was wondering if anyone may happen to have some of these gears laying around and wouldn’t mind parting with them, or if someone knew of another source to acquire them.

Thanks so much

Steve

LUXCUT-1336BH

MFG 1986

TAIWAN

A few years ago I acquired this lathe from my uncle who was unfortunately unable to use it due to failing health. It’s served me well and I very much enjoy my new hobby and I’m happy it’s still in the family. My latest project requires me to cut a 1.5 metric thread. It’s my understanding this is a “generic Taiwanese import lathe” circa the 1980’s with similar designs that were sold under many labels. The lathe didn’t come with a manual, however, I was able to source a generic one size fits all manual. According to it, this having an imperial lead screw, I’ll need a couple of change gears to be able to cut metric threads. Unfortunately, they were not included when I acquired the lathe. I’ve read some threads where folks with similar lathes were able to source some parts from Grizzly as they apparently sold a version of this lathe, the G9249. On Grizzly’s website they offer 30t, 32t, and 46t change gears but unfortunately they are all back ordered.

According to the manual I have, I’ll need the 32t gear to cut 1.5 metric threads. I would like to have all three for future projects as well. I was wondering if anyone may happen to have some of these gears laying around and wouldn’t mind parting with them, or if someone knew of another source to acquire them.

Thanks so much

Steve

LUXCUT-1336BH

MFG 1986

TAIWAN