- Joined

- May 3, 2017

- Messages

- 1,997

What I have made is far more spartan than Mitch's and David's stellar work in this thread:

www.hobby-machinist.com

www.hobby-machinist.com

I'm usually pretty respectful of my tools and equipment, but I've never been satisfied with my relatively cheap tap and die holders. My tap wrench finally bit the dust at about the time I watched Mitch's thread, so rather than buying a new one, I decided to take a shot at making my own.

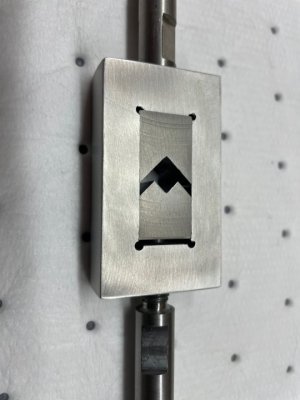

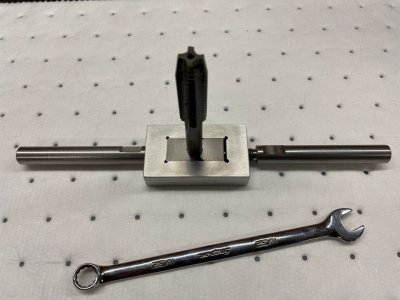

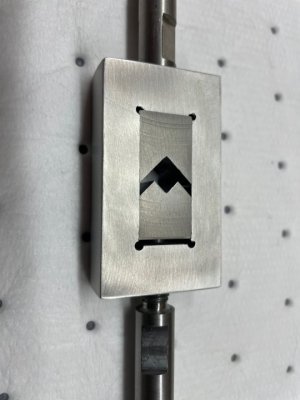

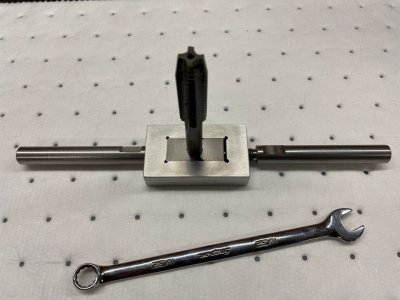

This more conventional tap wrench was fairly straightforward. Different from Mitch and David's, and not much to comment on it except that it required some very careful measuring and milling. The fit on my first attempt was too sloppy for my taste, so I re-made it with much tighter tolerances. It's much weightier than my deceased store-bought model, and it's machined very flat so I can use it on the lathe simply by pressing it against the quill on the tail stock. (I'm ruminating on building one that's dedicated to the lathe - something like the die holder described below. We'll see.)

The die holder is a little more creative. It occurred to me that the shank for a die holder is a little superfluous. Quite a bit of bulk and length could be removed if, instead of mounting the die in a shanked holder, it just slipped 'over' the quill instead of 'into' it. With tight enough tolerances, it should serve the same purpose. Here's my solution. The attached fourteen second video was taken after milling the blank that became the body of the holder. Make sure you have the volume turned up when you get to the end.

Regards,

Terry

Tailstock Tap & Die Holder

So another tool that has been a life-saver for me is this tap & die holder for the tailstock on my lathe. The plans for the main body I got from Clickspring, who does absolutely amazing work. I stayed pretty close to his plans with the exception of a die adapter that I decided to make for...

www.hobby-machinist.com

www.hobby-machinist.com

I'm usually pretty respectful of my tools and equipment, but I've never been satisfied with my relatively cheap tap and die holders. My tap wrench finally bit the dust at about the time I watched Mitch's thread, so rather than buying a new one, I decided to take a shot at making my own.

This more conventional tap wrench was fairly straightforward. Different from Mitch and David's, and not much to comment on it except that it required some very careful measuring and milling. The fit on my first attempt was too sloppy for my taste, so I re-made it with much tighter tolerances. It's much weightier than my deceased store-bought model, and it's machined very flat so I can use it on the lathe simply by pressing it against the quill on the tail stock. (I'm ruminating on building one that's dedicated to the lathe - something like the die holder described below. We'll see.)

The die holder is a little more creative. It occurred to me that the shank for a die holder is a little superfluous. Quite a bit of bulk and length could be removed if, instead of mounting the die in a shanked holder, it just slipped 'over' the quill instead of 'into' it. With tight enough tolerances, it should serve the same purpose. Here's my solution. The attached fourteen second video was taken after milling the blank that became the body of the holder. Make sure you have the volume turned up when you get to the end.

Regards,

Terry