- Joined

- Feb 17, 2021

- Messages

- 466

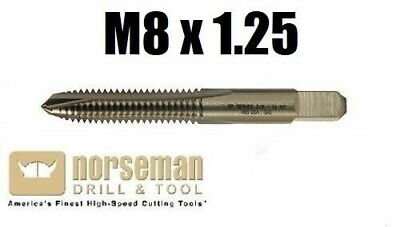

Am self taught with no one around to help and have a alot to learn .......right now am having a tap/die problem, drilled a hole for a tap and the drill was 9/32

then used a M8 1.25 tap. I can get about 1/8in. in the 6061 part then it stops and wont go any further. the part that needs die cut is steel which I tried to use a floating die setup from the TS but the die wont start cutting even when I chamfer the part , I tried both sides of the die still no luck

so we got 2 problems going on , tap and die

then used a M8 1.25 tap. I can get about 1/8in. in the 6061 part then it stops and wont go any further. the part that needs die cut is steel which I tried to use a floating die setup from the TS but the die wont start cutting even when I chamfer the part , I tried both sides of the die still no luck

so we got 2 problems going on , tap and die