- Joined

- May 25, 2016

- Messages

- 181

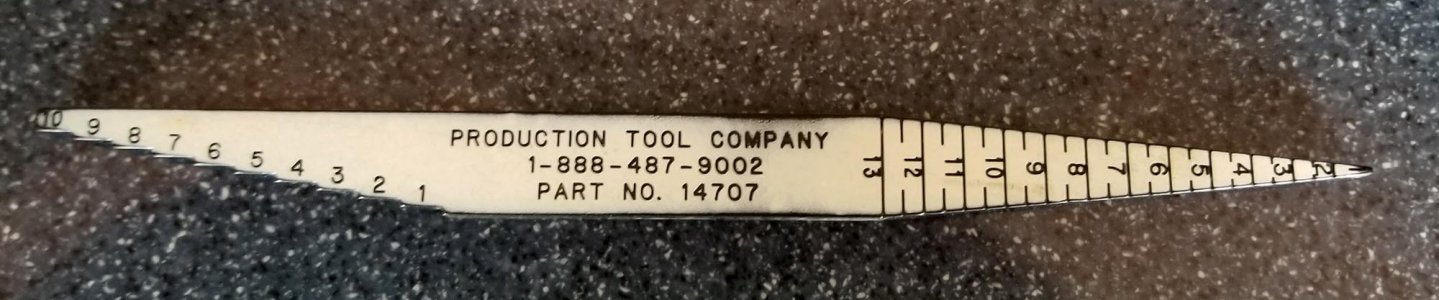

I acquired some Starrett taper gauges as part of a toolbox purchase from a retiring machinist.

Can anyone explain how they are used?

Are they still useful, or are they relics?

I can post pictures.

Tom

Sent from my iPhone using Tapatalk

Can anyone explain how they are used?

Are they still useful, or are they relics?

I can post pictures.

Tom

Sent from my iPhone using Tapatalk