Re: tapered bore or how I did it.

first I bored a hole lengthwise through a bit of 1" square bar, ground one side off with the angle grinder, drilled and tapped three holes into the bore.

Found an old drill bit, ground the end of the shank into a "D" profile and stoned it, hardened and tempered it where it got too hot in grinding.

Set in the square bar with three grub screws and hopefully I now had a boring bit. Talk about sling something together, I must make a real version next.

The compound was still set at the original angle so off I went.

I took a chance it would work because it sits a wee bit above centre but it did.

Heres the three parts so far, the large one still has to be slit so the tapered rod can expand the end.

The tapered rod still has to be threaded but I'm waiting for my fish gauge.

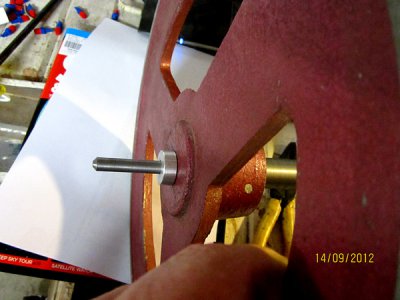

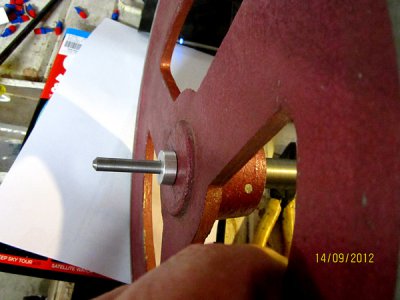

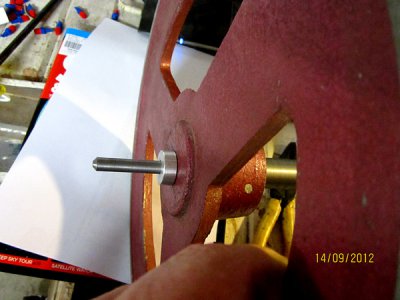

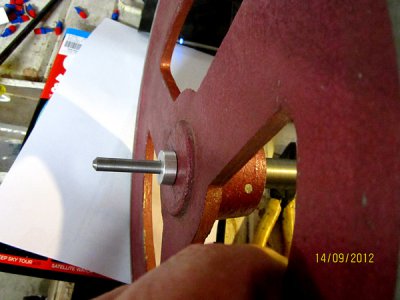

and this is the pulley it will all be going in so I can turn the lathe by hand.