Hi all, first time on your site and hoping for some help. Bought a 'tapping chuck' for the lathe from ebay. Made in China, of course, looks well made with 7 collets, BUT no instructions!! Have asked seller but of course no answer there, he has my $$....: : . Googled it, nothing. It has a collet spanner but I cant make it do anything ! -..so if anyone would be good enough to guide me how to use please, it would be appreciated thanks..:

: . Googled it, nothing. It has a collet spanner but I cant make it do anything ! -..so if anyone would be good enough to guide me how to use please, it would be appreciated thanks..:

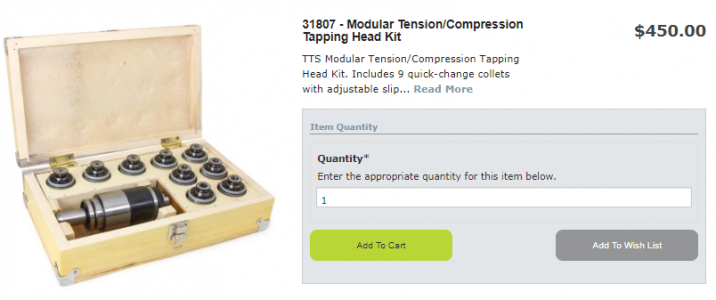

Attachments

Last edited:

now that i think about it more.....will check tomorrow when its daytime lol Thanks

now that i think about it more.....will check tomorrow when its daytime lol Thanks