I recently had a project that required making a puller for a pickup truck rear axle bearing. The bearing housing had 12x1.25mm threaded studs to pull on. This was my solution that worked very well but thats not what the thread is about. I had spiral point taps so i was able to muttle through, but i immediately ordered a spiral flute tap for future projects. I needed a die to clean up the rusty threads on the studs but i didn't have that either so i ordered an Interstate brand die.

The real question is about what thread diameters and pitches do you see on automobiles the most.

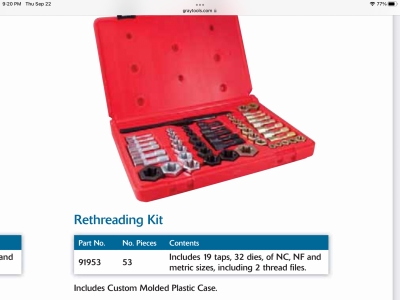

I have all the standard sizes and usually coarse and fine threads in each metric size.

I had taps in 12x1.25, 12x1.5, and 12x1.75. I'm better equipped now. I'd like to know what other less common sizes i can stock up on for my unpredictable future. Lol.

Don't tell me to wait to order it. I want to expand my selection ahead of time.

The real question is about what thread diameters and pitches do you see on automobiles the most.

I have all the standard sizes and usually coarse and fine threads in each metric size.

I had taps in 12x1.25, 12x1.5, and 12x1.75. I'm better equipped now. I'd like to know what other less common sizes i can stock up on for my unpredictable future. Lol.

Don't tell me to wait to order it. I want to expand my selection ahead of time.