- Joined

- Sep 14, 2014

- Messages

- 438

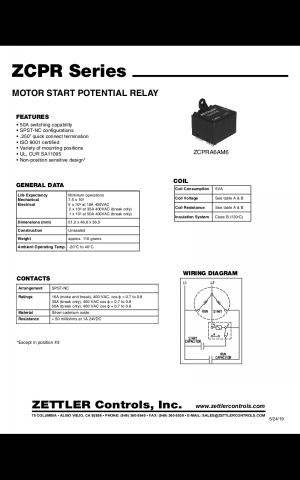

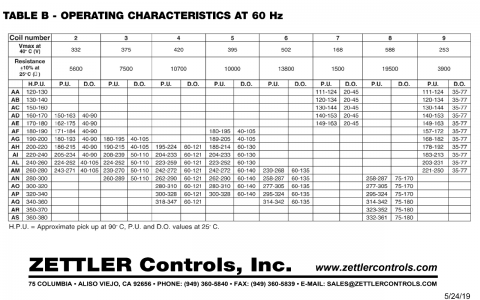

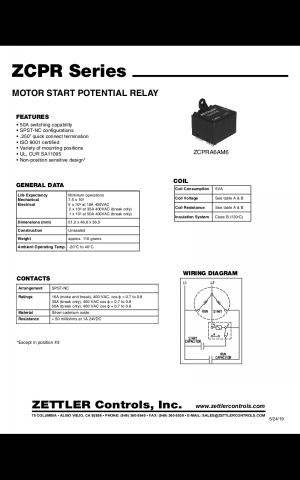

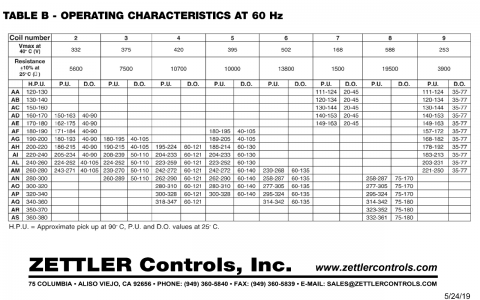

Hello, Happy Holidays and a not receiving a quick answer is not a crisis. I have a static phase converter with a Zettler ZCPR series , 5 coil I want to test and need guidance. I'm trying to figure out if I fried it pulling momentary 89a through it. Table A is for 60hz. In learning that "P.U." is pick up value and "D.O." is drop out value (professional peeve against any initials, initialism, or acronym not spelled out at least once in any document), haven't figured out what "H.P.U" is yet (hysteresis? the feed back voltage? ), but I figured out how to read the table.

Mine is an "AI" series.

The listed max break point is 50a

My input voltage is 243.

Resistance is 10k ± 10% @ 25°C/70°F.

V max is 395

PU is 203v

DO is 60 - 130v

H.P.U is ~ 220v - 240v @ 90°C/194°F

As a reference I have a 3hp 10EE I'm testing. The peak start amperage is ~ 89 and settles out @ 11.

How do I test it?

TIA

Ron

Mine is an "AI" series.

The listed max break point is 50a

My input voltage is 243.

Resistance is 10k ± 10% @ 25°C/70°F.

V max is 395

PU is 203v

DO is 60 - 130v

H.P.U is ~ 220v - 240v @ 90°C/194°F

As a reference I have a 3hp 10EE I'm testing. The peak start amperage is ~ 89 and settles out @ 11.

How do I test it?

TIA

Ron