-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Giant Binocular

- Thread starter savarin

- Start date

- Joined

- Aug 22, 2012

- Messages

- 4,116

A lot

It breaks down into three sections, base, bottom half and top half.

I've been a bit aprehensive to place it in the back of the suv yet just in case it doesnt fit. A rough check seems to say it will, just, but if it doesnt then thats another problem.

I can lift the base and the top half ok but the bottom half will be a bit too much for me alone when the mirrors are in.

Hmm, maybe on wheels so I can keep it assembled and wheel it out when I want to..........

I'm playing with the stand today attempting to clarify a couple of things but my brain seems to be operating like this

It breaks down into three sections, base, bottom half and top half.

I've been a bit aprehensive to place it in the back of the suv yet just in case it doesnt fit. A rough check seems to say it will, just, but if it doesnt then thats another problem.

I can lift the base and the top half ok but the bottom half will be a bit too much for me alone when the mirrors are in.

Hmm, maybe on wheels so I can keep it assembled and wheel it out when I want to..........

I'm playing with the stand today attempting to clarify a couple of things but my brain seems to be operating like this

- Joined

- Aug 22, 2012

- Messages

- 4,116

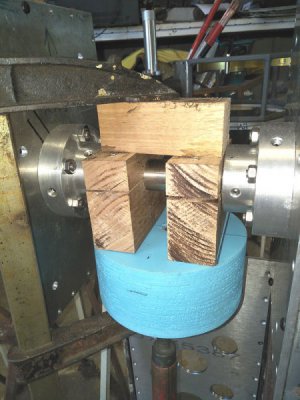

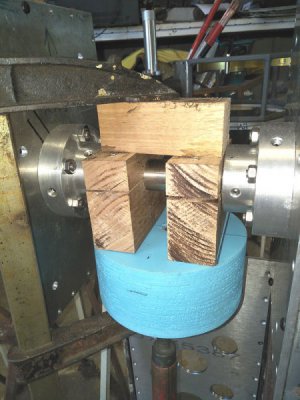

This is roughly what I will be doing for the pivot bearings.

I'm considering casting those wooden blocks in brass and squaring them up on the lathe, boring then for the shaft splitting them so they can be finger tightened and hinged for easy assembly and bolting them from underneath that blue cap (I'm changing this from a cast ally part to a steel fabrication) I first thought of casting them in aluminium but decided brass would be better with no galling.

Can anyone think of a reason not to use brass or if something better could be used.

I have decided to make the internal unit that holds the bearings for the azimuth system from some steel plate and short lengths like the bottom unit of the pier.

This meant I had to weld both sides of some 150mm wide plate so I could turn a 154mm dia circle.

I hacked the corners off with the trusty old angle grinder and turned it using a braised carbide tool that I ground to a sharp edge and left a small flange that will sit on top of the tube.

Then I flipped it around to bore a recess to hold a 90mm dia taper roller bearing.

Not finished yet but it was tea time.

I'm considering casting those wooden blocks in brass and squaring them up on the lathe, boring then for the shaft splitting them so they can be finger tightened and hinged for easy assembly and bolting them from underneath that blue cap (I'm changing this from a cast ally part to a steel fabrication) I first thought of casting them in aluminium but decided brass would be better with no galling.

Can anyone think of a reason not to use brass or if something better could be used.

I have decided to make the internal unit that holds the bearings for the azimuth system from some steel plate and short lengths like the bottom unit of the pier.

This meant I had to weld both sides of some 150mm wide plate so I could turn a 154mm dia circle.

I hacked the corners off with the trusty old angle grinder and turned it using a braised carbide tool that I ground to a sharp edge and left a small flange that will sit on top of the tube.

Then I flipped it around to bore a recess to hold a 90mm dia taper roller bearing.

Not finished yet but it was tea time.

- Joined

- Aug 22, 2012

- Messages

- 4,116

finished the first plate for the azimuth bearing.

this sits into the main pier tube

and the 90mm taper roller bearing sits into the recess.

Normally I would use a thick enough plate so the bearing can sit in it deeper but I didnt have any other material.

So a major question - as there is no real pressure on these bearings and zero speed do you think the small recess is sufficient to hold them?

They cant move sideways and will be set with locktight

The plate than holds the altitude bearings will sit on this.

this sits into the main pier tube

and the 90mm taper roller bearing sits into the recess.

Normally I would use a thick enough plate so the bearing can sit in it deeper but I didnt have any other material.

So a major question - as there is no real pressure on these bearings and zero speed do you think the small recess is sufficient to hold them?

They cant move sideways and will be set with locktight

The plate than holds the altitude bearings will sit on this.

- Joined

- Jan 2, 2016

- Messages

- 1,953

Will the shaft going through it be secured by another bearing, or something to keep things from coming apart if moved?

If just relying on gravity, I would do another ring as Baron suggested, but make it tighten able, either with screws going straight in, or a split and screw design, like many shaft collars. Just one less piece for someone to loose when moving.

If just relying on gravity, I would do another ring as Baron suggested, but make it tighten able, either with screws going straight in, or a split and screw design, like many shaft collars. Just one less piece for someone to loose when moving.

- Joined

- Aug 22, 2012

- Messages

- 4,116

I will be welding 6 vertical bars to another plate like I did here

https://www.hobby-machinist.com/threads/the-giant-binocular.55688/ post 16

A smaller taper roller bearing will be held at the bottom with a central shaft holding everything together and the whole assembly bolted into the pier.

This central shaft has to hold the top plate very securely as I will be using a friction bolt between them as a brake to the free motion.

https://www.hobby-machinist.com/threads/the-giant-binocular.55688/ post 16

A smaller taper roller bearing will be held at the bottom with a central shaft holding everything together and the whole assembly bolted into the pier.

This central shaft has to hold the top plate very securely as I will be using a friction bolt between them as a brake to the free motion.