- Joined

- Nov 25, 2015

- Messages

- 335

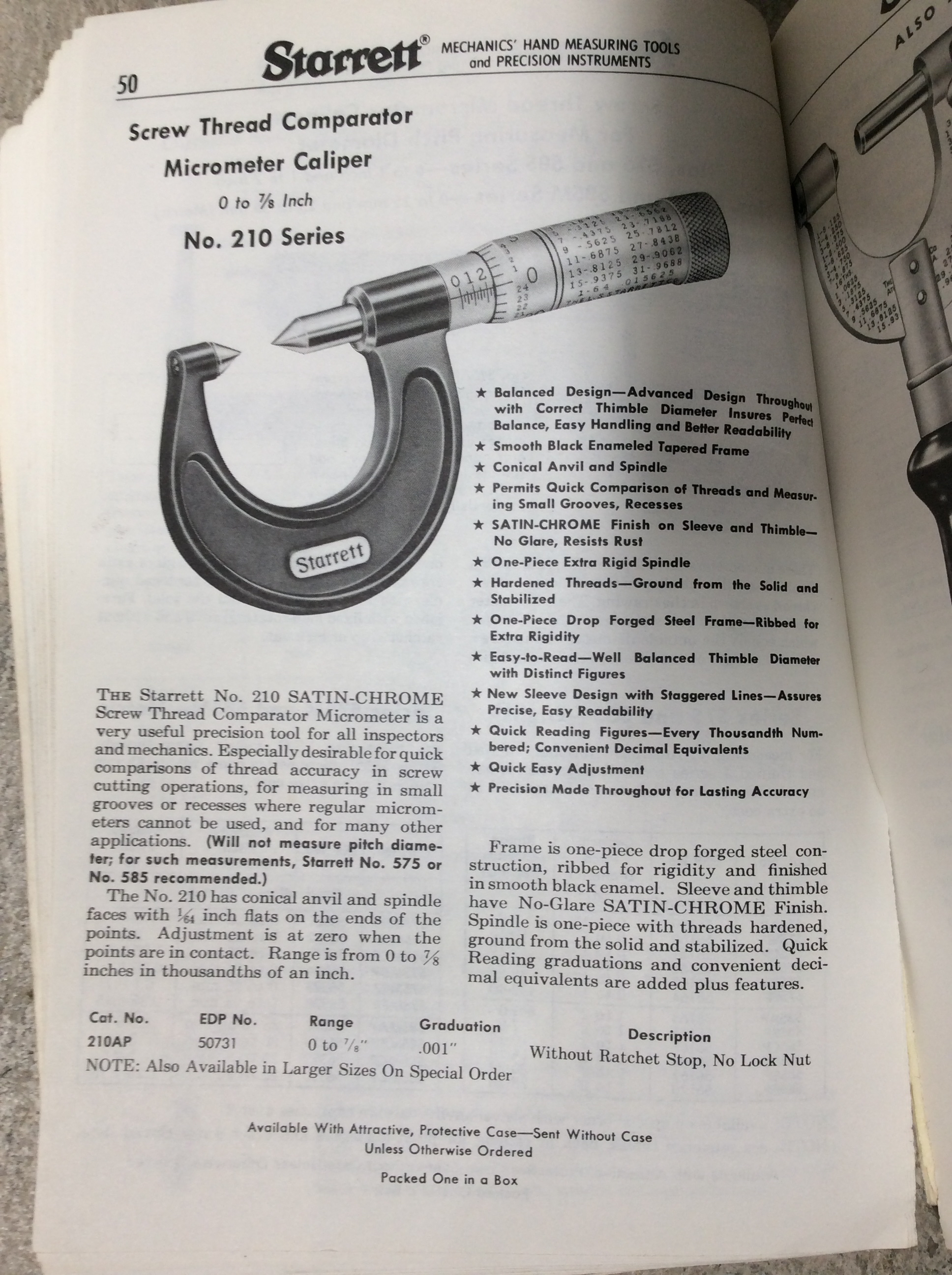

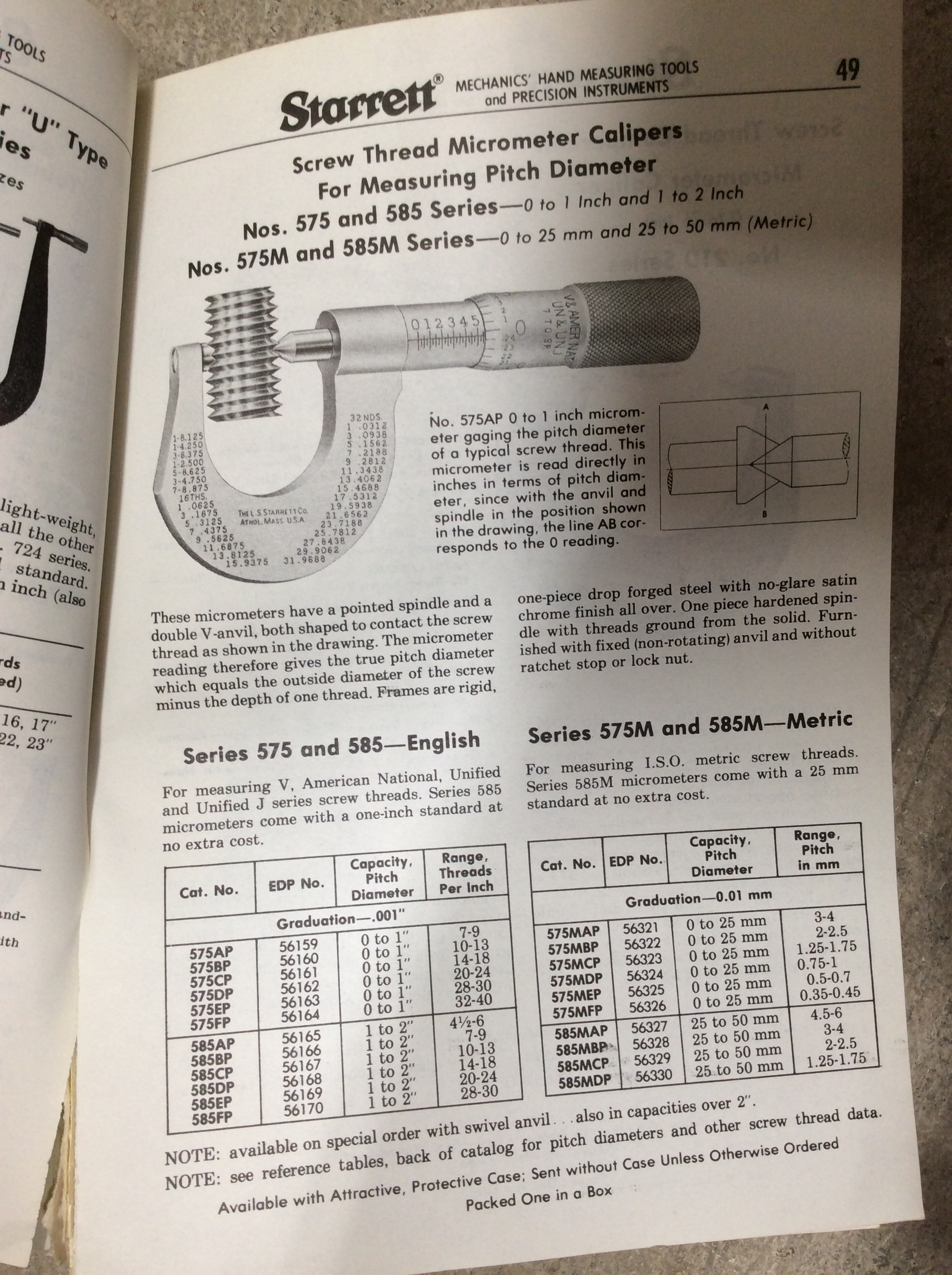

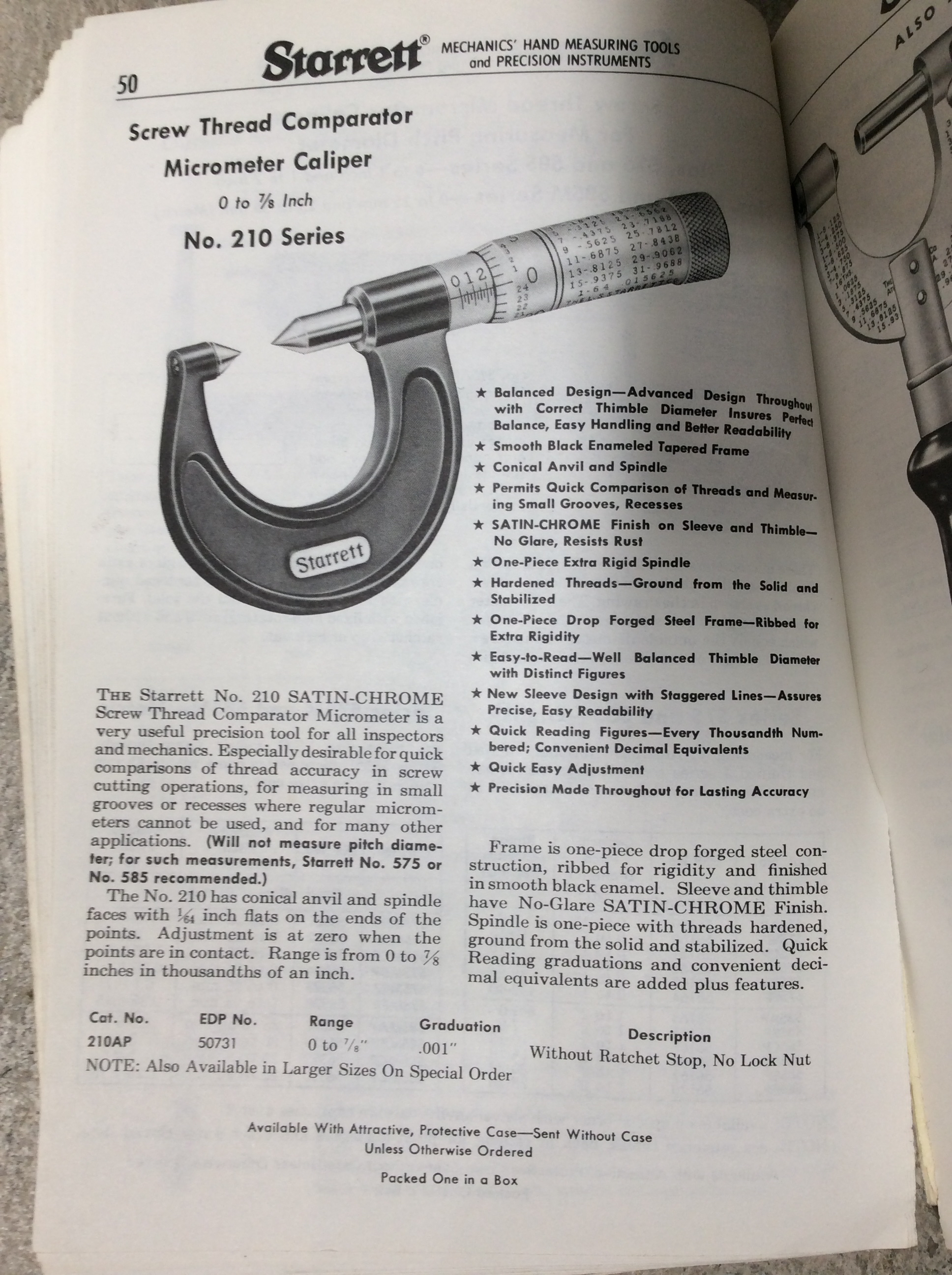

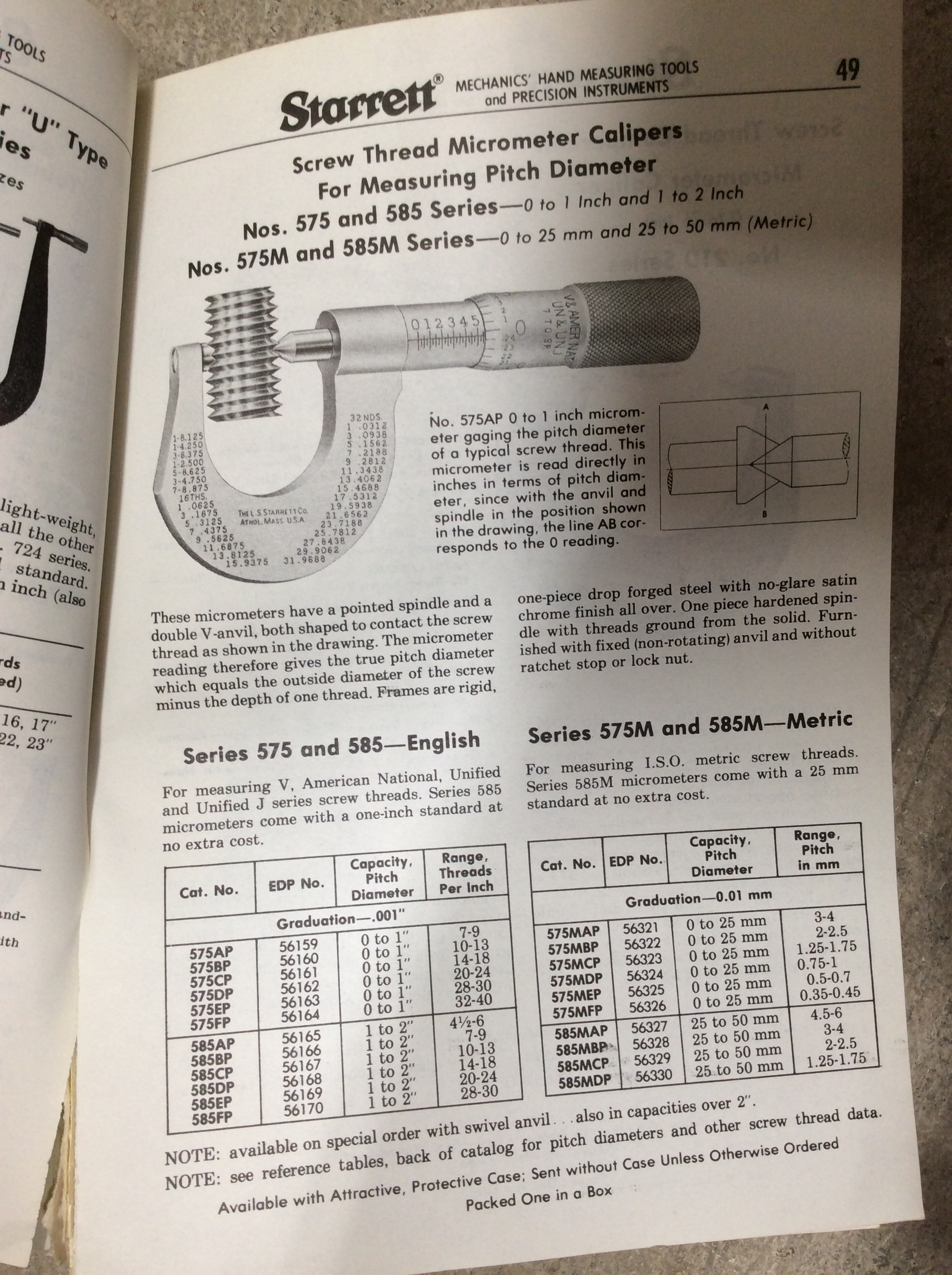

Hey everyone. I have a question regarding Thread Micrometers. I have in my tool chest a Starrett 210A Screw Thread Micrometer. I also have 3 Starrett 575 Screw Thread Micrometer Callipers for measuring pitch diameter (14-20, 22-30, 32-40 TPI) To my question..... Which do I use as a hobby guy when I want to see how close I am to being done threading. Essentially what measurement are each of these reading, or do I have this all wrong? When single point threading I turn the major diameter, then start threading..... which mic tells me when to stop?

Regards,

Derek.

Sent from my iPad using Tapatalk

Regards,

Derek.

Sent from my iPad using Tapatalk