- Joined

- Sep 23, 2011

- Messages

- 72

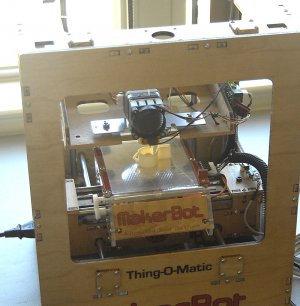

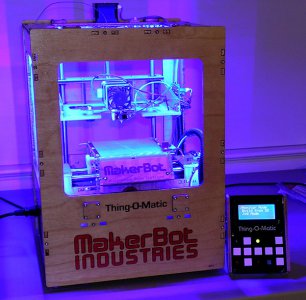

I built one of the 3D printers from MakerBot, it's called the Thing-O-Matic. It's pretty neat. I've had most every other type of machine tool over the years, nothing is quite like this.

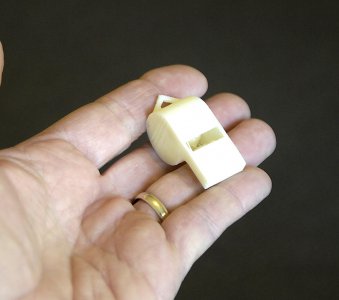

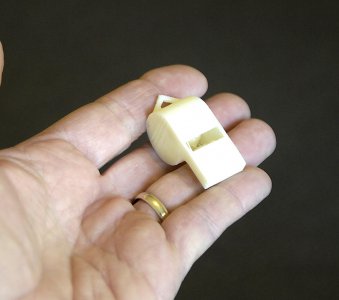

The first thing most people make is the whistle. It's an example file supplied with the CAM software.

I also designwd a set of 10DP gears in Alibre Design. The red spur gear would be easy to make on a lathe and mill, but the green internal tooth ring gear would be another story.

I'm not sure yet what I'll use it for, but it would be great for replacing broken plastic parts. It may also work well for making investment casting patterns.

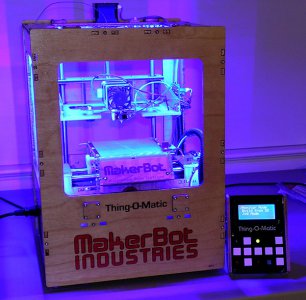

Today I "pimped-it-up" a bit with some blue LED strips.

The first thing most people make is the whistle. It's an example file supplied with the CAM software.

I also designwd a set of 10DP gears in Alibre Design. The red spur gear would be easy to make on a lathe and mill, but the green internal tooth ring gear would be another story.

I'm not sure yet what I'll use it for, but it would be great for replacing broken plastic parts. It may also work well for making investment casting patterns.

Today I "pimped-it-up" a bit with some blue LED strips.