- Joined

- Apr 1, 2014

- Messages

- 13

Would love to hear from other Schaublin owners.

The lathe is a 102VM, which is the screw cutting version of the 102. It's equipped with the overhead drive system for grinding/milling, coolant system in the right side of the stand, and a tripan quick change tool post. The lathe left the factory in June of 1949 and was completely rebuilt by the Schaublin factory in 1983.

The milling machine is a series 13 universal milling machine. It is a true universal mill with a tilting/rotating table, vertical head, horizonal setup,

high speed drilling head with quill, a slotting head, and change geared drive from the table to a dividing head for spiral milling. The mill left the factory in 1974.

Again, would love to hear from other Schaublin owners. I'm a member of the Yahoo Schaublin group, but find it extremely hard to navigate/post on that site.

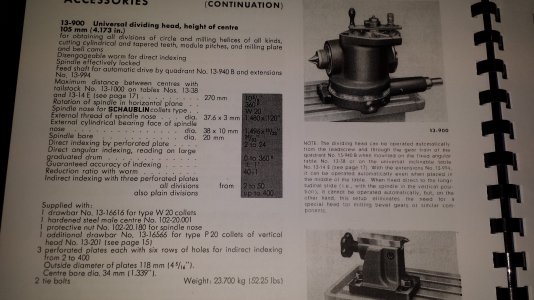

One item I'm looking for is a tail stock for my dividing head. I know the odds are slim to none, but I found the change gears for the spiral milling after searchingfor 20 years, so you never know.

The lathe is a 102VM, which is the screw cutting version of the 102. It's equipped with the overhead drive system for grinding/milling, coolant system in the right side of the stand, and a tripan quick change tool post. The lathe left the factory in June of 1949 and was completely rebuilt by the Schaublin factory in 1983.

The milling machine is a series 13 universal milling machine. It is a true universal mill with a tilting/rotating table, vertical head, horizonal setup,

high speed drilling head with quill, a slotting head, and change geared drive from the table to a dividing head for spiral milling. The mill left the factory in 1974.

Again, would love to hear from other Schaublin owners. I'm a member of the Yahoo Schaublin group, but find it extremely hard to navigate/post on that site.

One item I'm looking for is a tail stock for my dividing head. I know the odds are slim to none, but I found the change gears for the spiral milling after searchingfor 20 years, so you never know.

Last edited: