- Joined

- Nov 21, 2010

- Messages

- 1,602

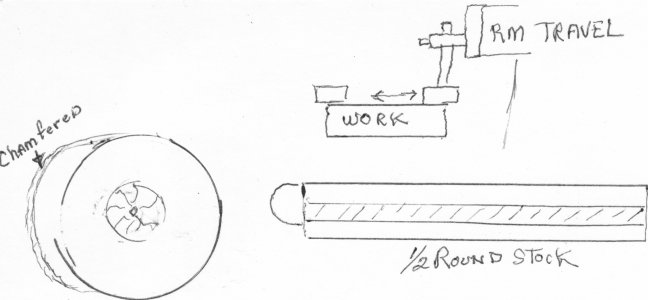

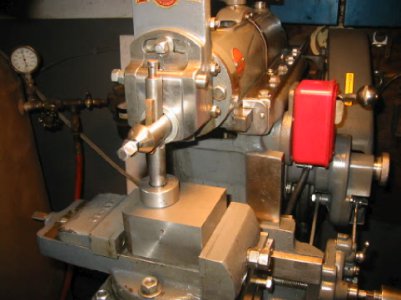

I made a couple sets of 1-2-3- blocks on my lathe, then onto the shaper for a very close finale size. Looks very good

and sat there giving thoughts of being a little better. Another of my- what ifs? I faced off about an inch round and

camf. it. Its flat and smooth. I welded stock to fit the shaper holder and installed it. The hard part is to tram this

i havent named it yet, to the ram so the work is perfectly flat with the work. I adjusted my ram so it does not come

off the work maybe, a little off the work . With feed on with not too much pressure, a little valve grinding compound,

I have to get the feel for just enough. That was a big wow. I go to finer compound amazing. I suppose you can even

go to toothpaste. I did two and the test was amazing that my two stick together just like a magnet. They

really look like a mirror. Again I had a hard look at this and today I will do a redesign. This time Ill take a ball end

to this on the lathe and put a ball (end) on the tool holder it will follow the work and dont have to tram it. Just another

attachment for the draw. sam a fine precision surface grinder with no dust

and sat there giving thoughts of being a little better. Another of my- what ifs? I faced off about an inch round and

camf. it. Its flat and smooth. I welded stock to fit the shaper holder and installed it. The hard part is to tram this

i havent named it yet, to the ram so the work is perfectly flat with the work. I adjusted my ram so it does not come

off the work maybe, a little off the work . With feed on with not too much pressure, a little valve grinding compound,

I have to get the feel for just enough. That was a big wow. I go to finer compound amazing. I suppose you can even

go to toothpaste. I did two and the test was amazing that my two stick together just like a magnet. They

really look like a mirror. Again I had a hard look at this and today I will do a redesign. This time Ill take a ball end

to this on the lathe and put a ball (end) on the tool holder it will follow the work and dont have to tram it. Just another

attachment for the draw. sam a fine precision surface grinder with no dust