-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thread mic, or wires?

- Thread starter dpb

- Start date

- Joined

- Nov 23, 2017

- Messages

- 1,191

Which do you find gives easier, more repeatable results?

I perfer thread gauges but sadly those don't check multiple sizes.... A thread mic is far more expensive than a the wires but it is easier to use...

- Joined

- Nov 27, 2012

- Messages

- 7,862

Both should be fairly good at repeating as long as what you are using isn't junk. As said, thread mics are expensive. I have one with interchangeable anvils for 0-1". With mics are you limited to diameter range & thread pitch range unless you get one with interchangeable anvils. Thread wires are inexpensive & work well but take a little longer. Can also be cumbersome if you don't have 3 hands but there are good ideas for holding aids if you need. If you need to measure a wide range & not that often thread wires might be a better choice.

- Joined

- Jan 31, 2016

- Messages

- 11,474

I don't have the need for thread mics , ring gages or plug gages any longer !  A set of Pee Dee standard and metric wires reside in my box these days , and I haven't used them in 5 years . I think their about 15 bucks a set vs $$$$ for thread mics .

A set of Pee Dee standard and metric wires reside in my box these days , and I haven't used them in 5 years . I think their about 15 bucks a set vs $$$$ for thread mics .

A set of Pee Dee standard and metric wires reside in my box these days , and I haven't used them in 5 years . I think their about 15 bucks a set vs $$$$ for thread mics .

A set of Pee Dee standard and metric wires reside in my box these days , and I haven't used them in 5 years . I think their about 15 bucks a set vs $$$$ for thread mics .- Joined

- Nov 27, 2012

- Messages

- 7,862

I don't have the need for thread mics , ring gages or plug gages any longer !A set of Pee Dee standard and metric wires reside in my box these days , and I haven't used them in 5 years . I think their about 15 bucks a set vs $$$$ for thread mics .

They're a bit more than double that price now but Fisher is still making them. I've been meaning to buy a set but I haven't had a need for measuring pitch diameter in a while. I guess I better buy a set before they get more expensive or Fisher stops making them. Imports are $15 now.

- Joined

- Jan 31, 2016

- Messages

- 11,474

I honestly can't remember the last time I chased on a lathe . I had the cnc up until 99 and used my geometric heads on the smaller lathes . Probably mid-nineties making gun barrels . We had all the thread ring gages in all different classes back then . Heck , where I'm at today , I use a nut or a bolt for gages !  Times sure have changed .

Times sure have changed .

Times sure have changed .

Times sure have changed .- Joined

- Dec 20, 2012

- Messages

- 9,422

Actually, the Chinese thread mics are pretty reasonable. They come with interchangeable anvils and at least the Fowler one I used was quite good. I now have Tesa 0-1" and 1-2" thread mics but that's just bragging; tools at that level are stupid expensive and totally not necessary.

dpb, the Three Wire sets are relatively cheap. For every thread pitch you are checking, you have to use three wires; two on top and one on the bottom (or vice versa). Then you put a micrometer on top of those wires and take a reading. Then you use a formula that comes with the wire set to figure out the pitch of your thread. Then you cut until you reach the pitch range you are shooting for. With practice, this can be done fairly fast.

Thread mics are direct reading. Use the right anvils and close the mic down on the thread and read it directly, no formulas to calculate and no wires to drop into the chip pan. Faster, very accurate (in the thousandths) and simple to do.

Both work, especially if you are cutting threads to a certain accuracy class or if you're trying to fit a preexisting thread. In a hobby shop, most threads are cut to fit and are one off so measuring pitch isn't often done. I do it because its fun to hit a tolerance range but you can certainly get along without measuring pitches most of the time.

dpb, the Three Wire sets are relatively cheap. For every thread pitch you are checking, you have to use three wires; two on top and one on the bottom (or vice versa). Then you put a micrometer on top of those wires and take a reading. Then you use a formula that comes with the wire set to figure out the pitch of your thread. Then you cut until you reach the pitch range you are shooting for. With practice, this can be done fairly fast.

Thread mics are direct reading. Use the right anvils and close the mic down on the thread and read it directly, no formulas to calculate and no wires to drop into the chip pan. Faster, very accurate (in the thousandths) and simple to do.

Both work, especially if you are cutting threads to a certain accuracy class or if you're trying to fit a preexisting thread. In a hobby shop, most threads are cut to fit and are one off so measuring pitch isn't often done. I do it because its fun to hit a tolerance range but you can certainly get along without measuring pitches most of the time.

Thread mics are great no doubt! Limited in pitch diameter with anvil can get expensive.

Using wires is a skill I think one should learn along with the formulas. Even if it sits in the box for five years having used nuts and bolts for guages it s nice to have and know how to use them for that occasion you may need to hit a class of thread an offsize from your mics or maybe you want to tackle a double start acme thread one day. Try finding a nut for that one.

Just nice to have. Cheap and reliable!

Using wires is a skill I think one should learn along with the formulas. Even if it sits in the box for five years having used nuts and bolts for guages it s nice to have and know how to use them for that occasion you may need to hit a class of thread an offsize from your mics or maybe you want to tackle a double start acme thread one day. Try finding a nut for that one.

Just nice to have. Cheap and reliable!

- Joined

- Nov 23, 2014

- Messages

- 2,607

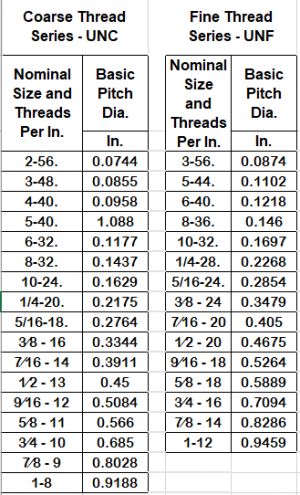

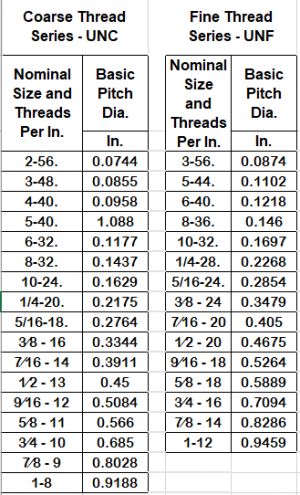

I have both and NEVER use the thread wires. I have two sets of Shars 0-1", 1-2" and one 2-3" screw pitch micrometers. The mic's were around $60 each delivered. Printed up copies of the chart below and have those in the 0-1" cases for quick reference of the pitch diameters. There are other more comprehensive charts out there with oddball threads and metric in case they're not on my quick reference chart. If I was to do a 1"-20 thread (for example), it's easy math for the pitch diameter. Take the 1/4" - 20 of 0.2175" as the cue. 0.25" - 0.2175" is 0.0325". So the pitch diameter of a 1" - 20 thread would be 1.000" - 0.0325" or 0.9675".

That being said, I have $300 invested in screw pitch mic's. Never used the 2"-3" set, or the 1-2" setting at my Clausing lathe. If you only do occasional threading, the thread wires would be fine.

Bruce

That being said, I have $300 invested in screw pitch mic's. Never used the 2"-3" set, or the 1-2" setting at my Clausing lathe. If you only do occasional threading, the thread wires would be fine.

Bruce