- Joined

- Sep 11, 2015

- Messages

- 293

I'm attempting to cut some 5/8-24 threads for some dies and have run into a little problem that I cant seem to figure out.

I did my first light pass to check the thread pitch. Its off ever so slightly. Since I was using a scrap piece of O1, I continued to cut them anyways. Because you know, you can never have enough practice. Well I finish the threads and then I use my cheap little thread gauge on them. No match. The first 3-4 teeth on the gauge fit the threads, but anything past that is a no go. They are just ever so slightly off. I compared the gauge to some dies I already have, and it fits.

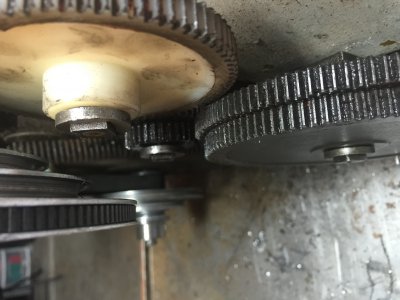

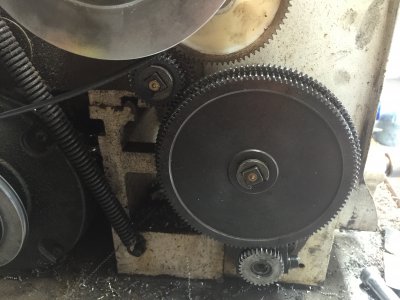

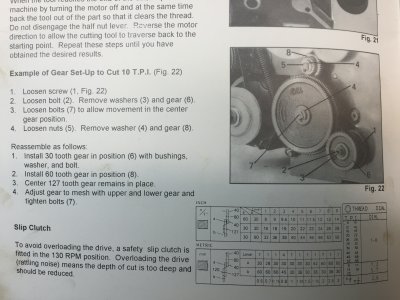

I'm clearly not seeing what the problem is. Does anybody have anything for me to check? I triple confirmed I have the correct gears and the box set to the correct feed. The Jet 920 I'm using says to use 30 tooth gears and set the gearbox to 7. Those are correct. So I'm lost.

I did my first light pass to check the thread pitch. Its off ever so slightly. Since I was using a scrap piece of O1, I continued to cut them anyways. Because you know, you can never have enough practice. Well I finish the threads and then I use my cheap little thread gauge on them. No match. The first 3-4 teeth on the gauge fit the threads, but anything past that is a no go. They are just ever so slightly off. I compared the gauge to some dies I already have, and it fits.

I'm clearly not seeing what the problem is. Does anybody have anything for me to check? I triple confirmed I have the correct gears and the box set to the correct feed. The Jet 920 I'm using says to use 30 tooth gears and set the gearbox to 7. Those are correct. So I'm lost.