- Joined

- Dec 23, 2020

- Messages

- 59

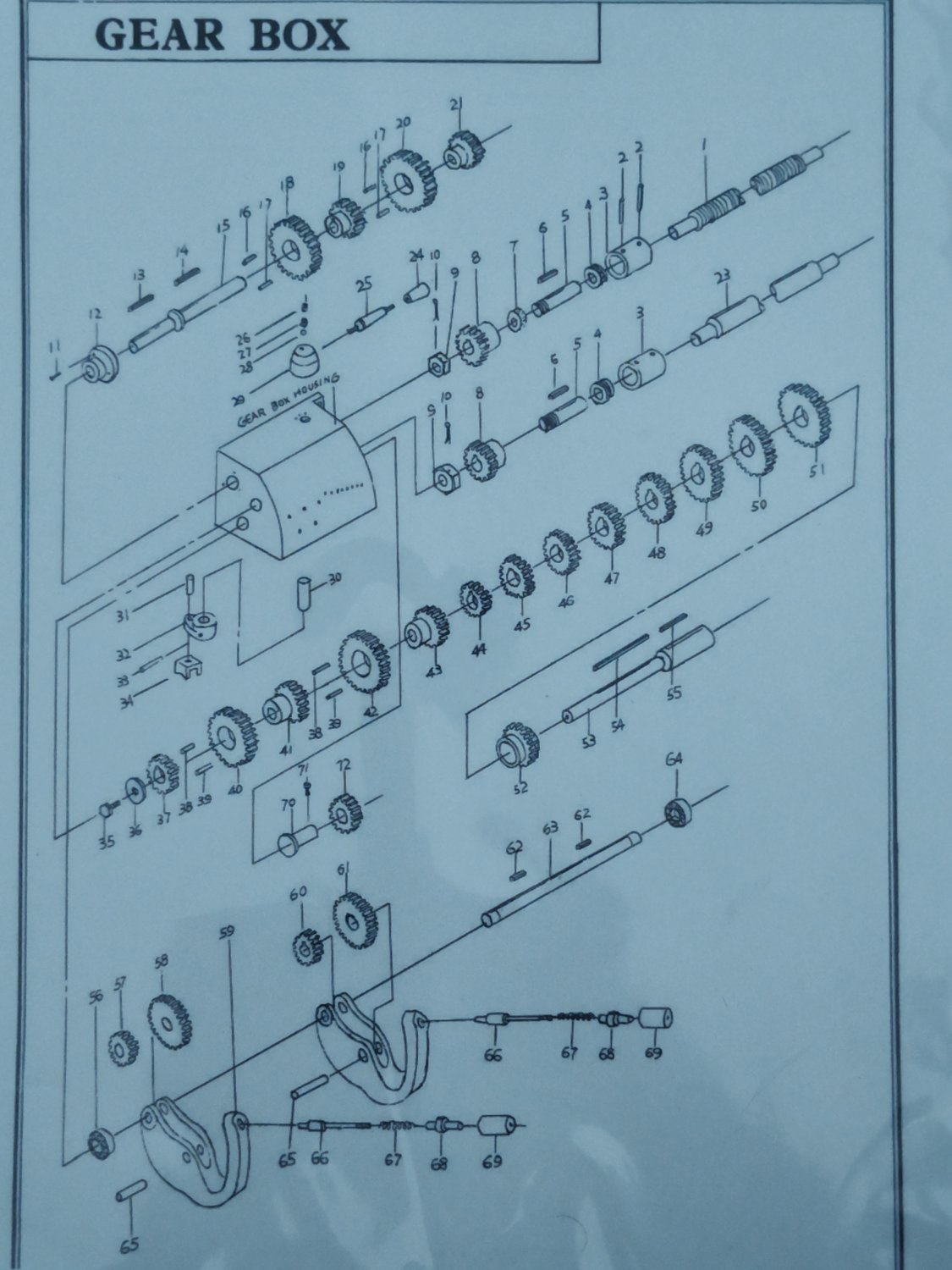

I'm continuing down the path of disassembling and cleaning my Tida / Samson 5aa. Being new to this, I'm probably being a bit too gentle for fear of damaging anything but not sure.

I have everything out of the gearbox except shaft #15 with it's associated gears, pins, and key (14-21).

From the diagram, it looks like it should be able to be pulled or pressed out. I can get it to move about 3/8" lightly tapping with a drift, then it stops like its bottoming on something. I tried a little more pressure with a shop press, but only 2-3 pumps after easy movement stopped. Its enough pressure that the gears bind but not so much that it would have bent the shaft.

I don't see any set screws or pins holding the gears on, so do I just need to use more pressure with the shop press? Or do you guys see something I'm missing in the diagram?

Pins #16 & #17 are a question for me. Why would there be horizontal pins?

I have everything out of the gearbox except shaft #15 with it's associated gears, pins, and key (14-21).

From the diagram, it looks like it should be able to be pulled or pressed out. I can get it to move about 3/8" lightly tapping with a drift, then it stops like its bottoming on something. I tried a little more pressure with a shop press, but only 2-3 pumps after easy movement stopped. Its enough pressure that the gears bind but not so much that it would have bent the shaft.

I don't see any set screws or pins holding the gears on, so do I just need to use more pressure with the shop press? Or do you guys see something I'm missing in the diagram?

Pins #16 & #17 are a question for me. Why would there be horizontal pins?

Attachments

Last edited: