- Joined

- Nov 8, 2011

- Messages

- 1,678

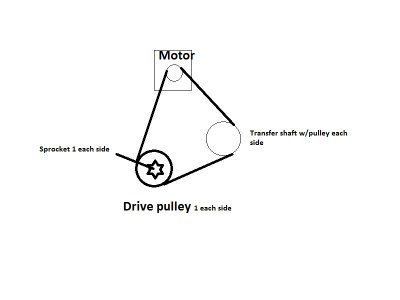

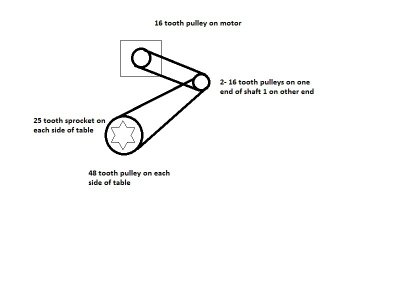

I'm gonna make my pulleys tomorrow hopefully for my cnc plasma table. I need to know what size I should use like XL, L ,H?

I also need the dimensions for the tooth profile so I can grind a cutter for this job. Not sure if I'll do it with a fly cutter or a regular cutter yet.

I need to make several about 3" dia. no bigger though.

I also need the dimensions for the tooth profile so I can grind a cutter for this job. Not sure if I'll do it with a fly cutter or a regular cutter yet.

I need to make several about 3" dia. no bigger though.