- Joined

- Aug 2, 2011

- Messages

- 146

Many of us hobbyists can neither afford or have space/power for a Bridgeport or even an RF-45 square column mill. Often we have to settle for one of the Rong Fu or RF clones -- RF-20, RF-25, RF-30 or Rf-31-- round column mill/driils.

I have both an HF mini-mill and and RF-31 (Taiwan made). And while the mini-mil is a nice for small parts, the RF-31 is in an entirely different league. The mill weighs well in excess of 400 pounds and you need an engine hoist or crane to move it. However, on craigslist you can often pick up a Rong Fu for just a little more cost than a mini-mill. I saw a nice RF-31 the other day for $375 including vise.

At any rate, being round columns, the Rong Fu's are notorious for losing tram whenever the head is moved up and down the round column. The R8 drawbar can also be a little annoying.

Searching for ways to improve my RF-31, I came across the following YouTube machining channel belonging to a video creator whose handle is "Cuppa Joe."

This is a link to Cuppa Joe's machining site with Rong Fu Mill/Drill information.

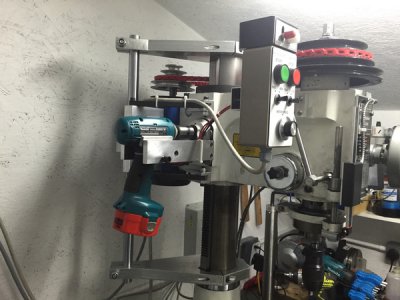

This ingenious machinist has developed a novel -- and relatively inexpensive -- way to fix the tram problem, and has made several other modifications to his RF-31 that have transformed it into a real workhorse.

As a joke he calls his videos about his improvements to his RF-31 either "Wrong Fu" or "Wrong Fu." This may have hurt hits to his site when those titles are bypassed by Google searches.

Just today in response to a backchannel email exchange I have been having with him, Joe released this overview video showing his many modifications.

I encourage any of you Rong Fu mill-drill owners, or prospective owners, to take a few minutes to visit Joe's YouTube site. I'm sure you'll find it worthwhile.

I have both an HF mini-mill and and RF-31 (Taiwan made). And while the mini-mil is a nice for small parts, the RF-31 is in an entirely different league. The mill weighs well in excess of 400 pounds and you need an engine hoist or crane to move it. However, on craigslist you can often pick up a Rong Fu for just a little more cost than a mini-mill. I saw a nice RF-31 the other day for $375 including vise.

At any rate, being round columns, the Rong Fu's are notorious for losing tram whenever the head is moved up and down the round column. The R8 drawbar can also be a little annoying.

Searching for ways to improve my RF-31, I came across the following YouTube machining channel belonging to a video creator whose handle is "Cuppa Joe."

This is a link to Cuppa Joe's machining site with Rong Fu Mill/Drill information.

This ingenious machinist has developed a novel -- and relatively inexpensive -- way to fix the tram problem, and has made several other modifications to his RF-31 that have transformed it into a real workhorse.

As a joke he calls his videos about his improvements to his RF-31 either "Wrong Fu" or "Wrong Fu." This may have hurt hits to his site when those titles are bypassed by Google searches.

Just today in response to a backchannel email exchange I have been having with him, Joe released this overview video showing his many modifications.

I encourage any of you Rong Fu mill-drill owners, or prospective owners, to take a few minutes to visit Joe's YouTube site. I'm sure you'll find it worthwhile.