- Joined

- Mar 27, 2017

- Messages

- 195

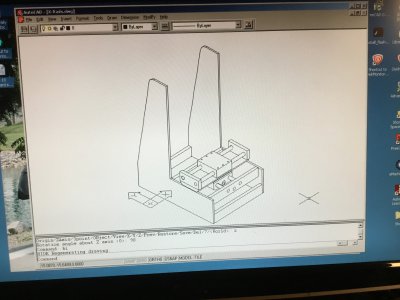

The drawings and construction of the magazines home made surface grinder is a very simple and home made project. My intention is to improve on the design by upgrading to ball screws and dovetail ways among other things. The basic design has merit as a shop made bench top grinder for the average home shop machinist. However the concept and execution along with other improvements will produce a very nice machine for passing down to my progeny. My focus is not on making a production machine but a personal project I can be proud to pass on to upcoming machinists just as we all do with shop made tooling and fixtures. In all my 60 plus years in the trade I hope to leave something behind to be remembered by besides my tools and fixtures, I am after all past the prime of life at 82 ! I do appreciate the input from all you gentlemen who have expressed your opinion and offered advice.

I am a newbie in this chat room age and wish I had started earlier. Thanks again!

I am a newbie in this chat room age and wish I had started earlier. Thanks again!