- Joined

- Oct 3, 2015

- Messages

- 983

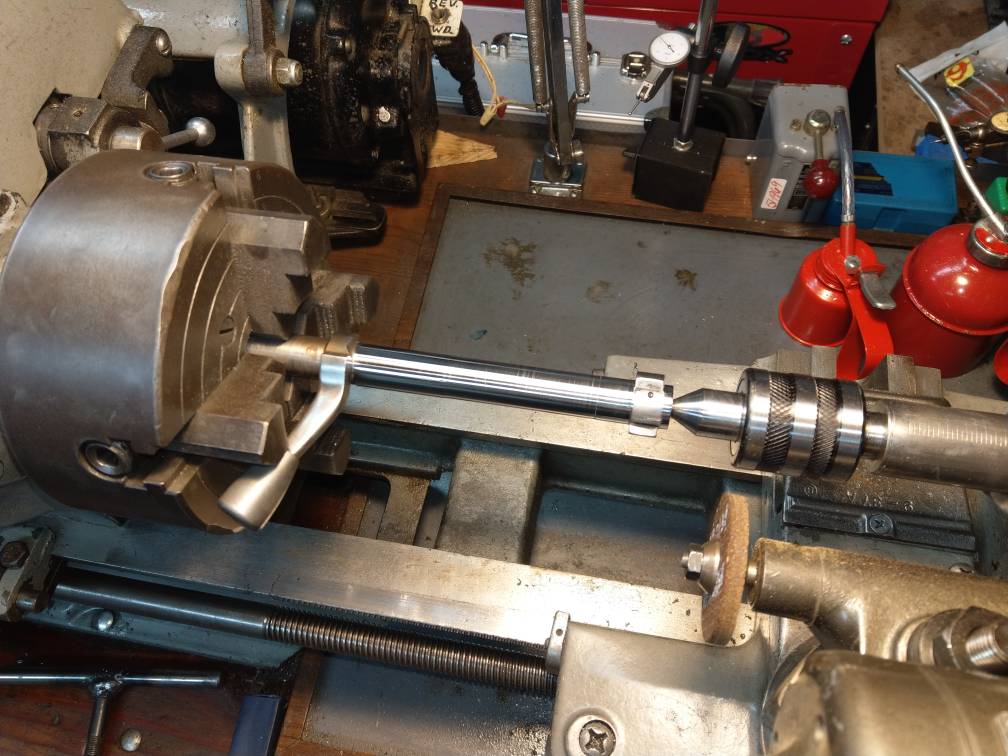

Your biggest dilemma will be keeping that skinny ass barrel from slipping in the blocks. Use a barrel vise like this

make the blocks from oak, and bed the barrel to the blocks with your favorite bedding compound. This gives 100% contact and no marring or scarring. This method has never failed for me.

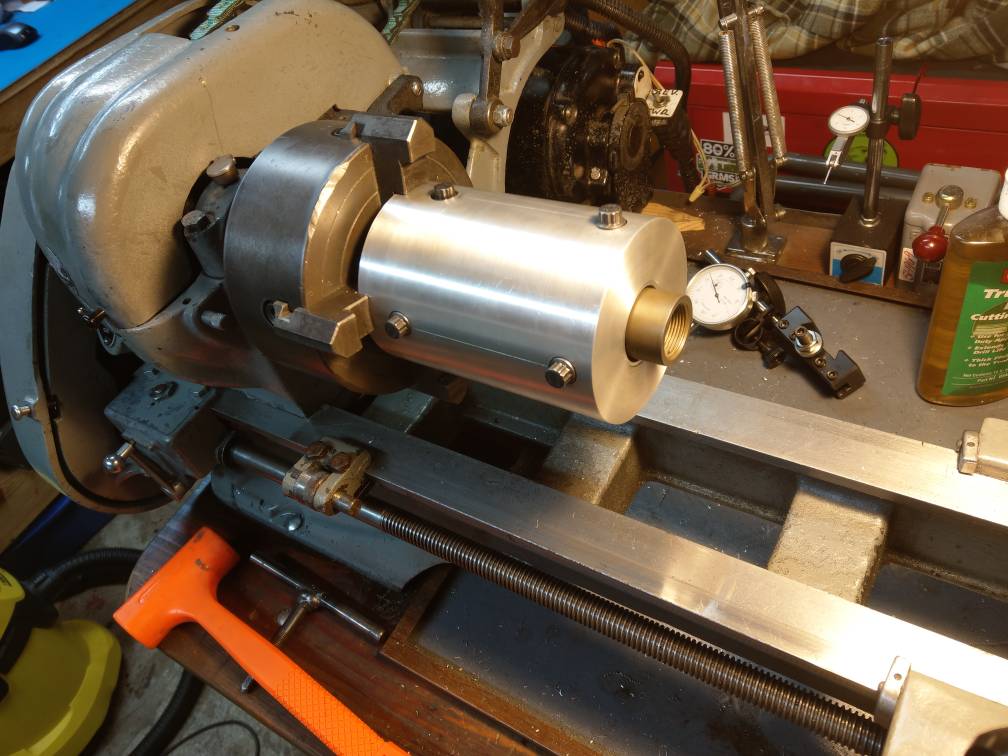

For larger barrels I use this set up

make the blocks from oak, and bed the barrel to the blocks with your favorite bedding compound. This gives 100% contact and no marring or scarring. This method has never failed for me.

For larger barrels I use this set up