HEY TOM!!

Sorry for shouting but I wanted to let you know that I tested the Tormach Superfly cutter on my RF-31 with a Baldor 1HP motor on it (soon to have a Baldor 2HP w/VFD). I needed to square a piece of 6061 for a project and it was the perfect project to assess the new cutter.

In a word, I was UNDERWHELMED.

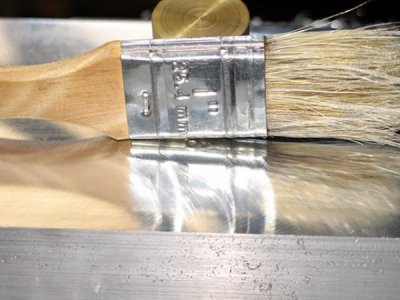

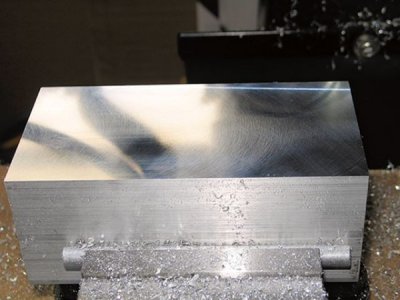

To be fair, I extended the cutter to flycut a 3" wide piece. Whether this has anything to do with the finish it produces I'm not sure. The deepest cut I took was only 0.010" but at 440 rpm the motor didn't even slow down. In fact, I heard no change in motor load so I suspect that Tormach's claims that this cutter works on low horsepower mills is true. A heavier cut might slow it but if you take reasonable cuts as we do when squaring a work piece then your mill should handle this tool without any issues.

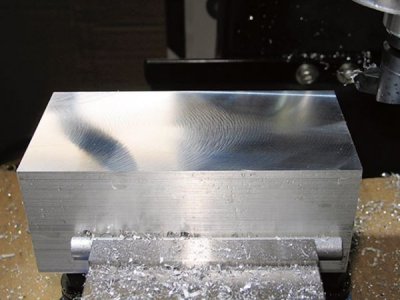

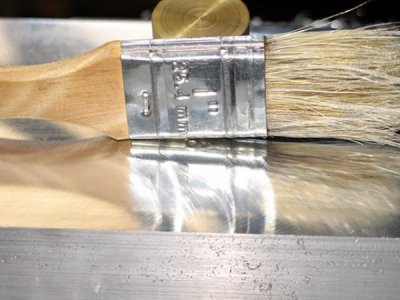

The tools cuts much cleaner on the front of the tool; the backside leaves slight ridges that are not palpable but are visible. This is seen when feeding in either direction in X, and it doesn't seem to matter what speed your spindle turns at or what the X-axis feed rate is; the pattern is the same.

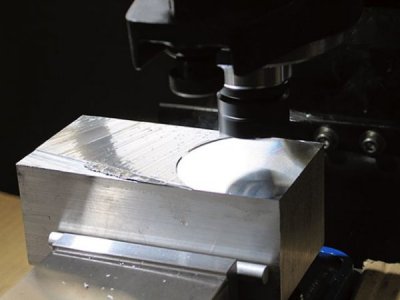

I initially tried it at 440 rpm. This is the cutting speed based on the cutting conditions on the insert box. It cut just fine but that ridged pattern is clear to see. Then I increased spindle rpm to 1800 to get near your 2000 rpm limit to show how it worked.

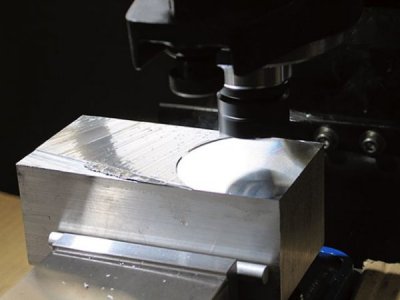

440 rpm start:

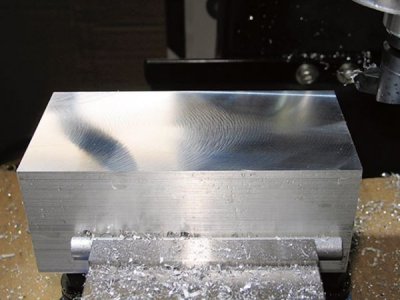

440 rpm finish:

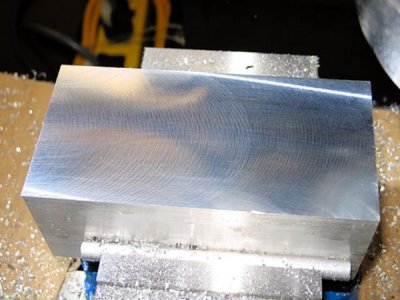

440 rpm climb finish, 0.003" doc:

1800 rpm, 005" doc:

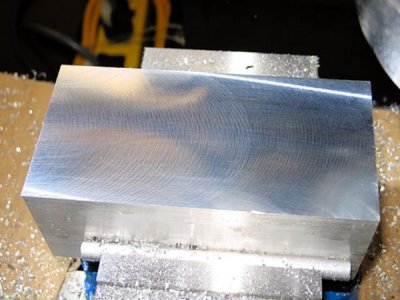

1800 rpm finish pass, 0.003" doc:

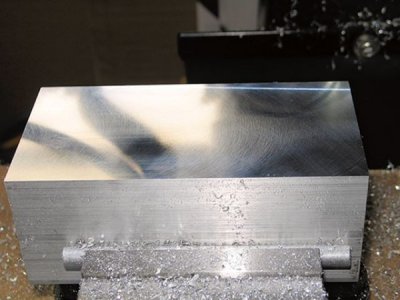

1800 rpm, 0.003" doc, not really a mirror finish in my book:

As I said, the finish is less finished than I expected. It may be that I need to learn how to use the tool properly but I've been using flycutters for 25+ years and I sorta know how to use the thing. This one cuts easily, can handle decent depths of cut and seems to create cutting loads that a 1HP motor can handle with no problem. It just doesn't finish anywhere near what I expected. Now, my baseline expectation is a Sherline inserted tip carbide flycutter. This tool will put a finish on aluminum that would frost your eyeballs so maybe my expectations may be a bit high.

With all that said, this is my opinion:

It does what they say and will produce a flat surface over a 3" wide area. If you only need it for squaring work pieces then it will work just fine. If you are expecting a super-fine finish that you can display without further finishing of the surface then keep looking - this is not the tool. It will work with your 1HP motor.

Things may change as I get used to the tool. Who knows, maybe I messed up locking down the insert (not very likely) or something. I do not regret buying it. Not many flycutters will cut a 3" wide surface unless you build it. Suburban Tools flycutter might work better but it is more costly. For me, this will have to do.