After seeing what can be done with treadmill motors I’ve been on the hunt for one , I found a free one on CL and here it is.

I don’t think it’s reversible as the brushes are at a slight angle. The flywheel fan didn’t want to come off , I found one of the resistors legs on the card broken , should be able to solder it back together.

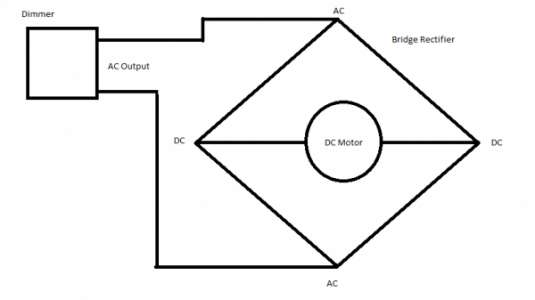

I guess my question is what will I have to get to make it work for ?? A belt sander ?.

Thanks for any / all advice

I don’t think it’s reversible as the brushes are at a slight angle. The flywheel fan didn’t want to come off , I found one of the resistors legs on the card broken , should be able to solder it back together.

I guess my question is what will I have to get to make it work for ?? A belt sander ?.

Thanks for any / all advice