Hello All,

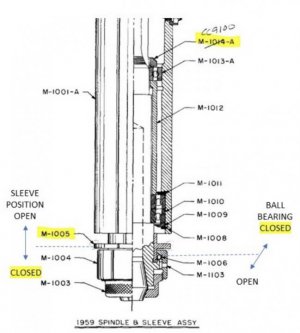

I recently acquired a Tree 2UVR and I am looking for a collet nose / collet retaining ring (part number M-1003).

I’ve called a few of the popular sources such as ZPS and another in Michigan (Eagle manufacturing) without any luck.

I was wondering if anyone may have a lead on one of these parts, and if not, at least some dimensions I could use to make my own. I understand that they are hardened which shouldn’t be too much of an issue for me to handle. I’m just more concerned about the type of fit of the collet nose/ring to the spindle.

Any help would be really appreciated s I haven’t had much luck elsewhere.

I recently acquired a Tree 2UVR and I am looking for a collet nose / collet retaining ring (part number M-1003).

I’ve called a few of the popular sources such as ZPS and another in Michigan (Eagle manufacturing) without any luck.

I was wondering if anyone may have a lead on one of these parts, and if not, at least some dimensions I could use to make my own. I understand that they are hardened which shouldn’t be too much of an issue for me to handle. I’m just more concerned about the type of fit of the collet nose/ring to the spindle.

Any help would be really appreciated s I haven’t had much luck elsewhere.