- Joined

- Jun 26, 2018

- Messages

- 1,733

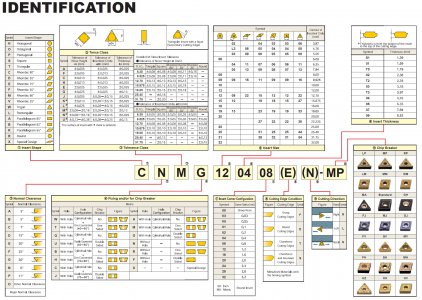

I'm not gonna lie, of all the mill/lathe knowledge I am slowly learning, insert decoding just IS NOT coming together for me. I have done times of searching, a lot of chart scanning, sat on the couch with a caliper measuring and cross referencing....but yeah, I'm not going to lie, this is NOT coming together for me.

I have talked to other newbs, this isn't uncommon. I will say it is more complicated than it needs to be and that there are ANSI and ISO, it makes it even more challenging. Here's my story, names have been changed to protect the innocent.....

I bought my lathe about 2 years ago, with good recommendations, I immediately changed to an AXA QCTP. I bought the Accusize 3/8" tool holders and in this time, I have needed to change the inserts. I want better quality inserts than the originals and I do mainly stainless. The C shaped insert tool some education, but was able to get a few different Kennametals. Done. This W shaped one has become comical in trying to replace it. I have been using it for 2 years and that has been through the earliest learning stages where uber light passes was about all I did, now I have learned that can actually over heat the tool...but I'll try to keep this in topic and wrap it up.

My first (extremely under thought through) purchase was WNMG inserts. Way wrong. My tool holder is swgcr06-2j and Accusize says WCMT 21.52 inserts. Went to ebay and found some really good ones,got them....too small. The sellers said you need WCMT 32.52 he did a swap with some addition cash and I got some SECO for stainless. Too big. I'll say there are more options in the ANSI name than the ISO, but they should be one and the same....NO?

I need help with this tool holder. Good, bad or indifferent, I'm not going back to ACCUSIZE. Maybe it's just pricip

I have talked to other newbs, this isn't uncommon. I will say it is more complicated than it needs to be and that there are ANSI and ISO, it makes it even more challenging. Here's my story, names have been changed to protect the innocent.....

I bought my lathe about 2 years ago, with good recommendations, I immediately changed to an AXA QCTP. I bought the Accusize 3/8" tool holders and in this time, I have needed to change the inserts. I want better quality inserts than the originals and I do mainly stainless. The C shaped insert tool some education, but was able to get a few different Kennametals. Done. This W shaped one has become comical in trying to replace it. I have been using it for 2 years and that has been through the earliest learning stages where uber light passes was about all I did, now I have learned that can actually over heat the tool...but I'll try to keep this in topic and wrap it up.

My first (extremely under thought through) purchase was WNMG inserts. Way wrong. My tool holder is swgcr06-2j and Accusize says WCMT 21.52 inserts. Went to ebay and found some really good ones,got them....too small. The sellers said you need WCMT 32.52 he did a swap with some addition cash and I got some SECO for stainless. Too big. I'll say there are more options in the ANSI name than the ISO, but they should be one and the same....NO?

I need help with this tool holder. Good, bad or indifferent, I'm not going back to ACCUSIZE. Maybe it's just pricip