-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trying to add a Model A apron to a SB 9" model C

- Thread starter Tim9

- Start date

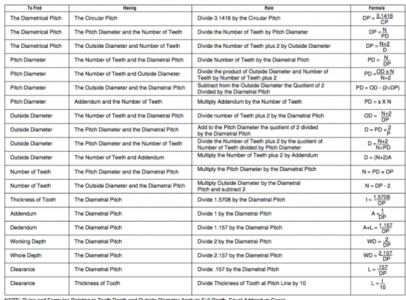

Make sure you also get the right number cutter. The Chinese ones are usually numbered backwards.

If you haven't already ...... Search the net and download Shop calc. It will figure the gear info automatically with your known info. It is a great program and free.

If you haven't already ...... Search the net and download Shop calc. It will figure the gear info automatically with your known info. It is a great program and free.

It is in my spare parts drawer. I removed it because I made a new screw when I made the large dial assemblies for my lathe. 10 teeth does sound correct.And thanks again Mark. I'm kind of confident now that it's 10 teeth so don't put yourself out.

Mark, I really appreciate the offer but the formulas say 10 teeth and the pictures I saw looked like 10 teeth so I'm going to go with 10 teeth. That said...If you can put your hands on it with out any effort...Then counting the teeth would reassure me even more. YET...If its any trouble or you have to dig through boxes, then please do not put yourself out. I'm pretty confident that it must be 10 teeth.

4

4GSR

Forum Guest

Register Today

Tim,

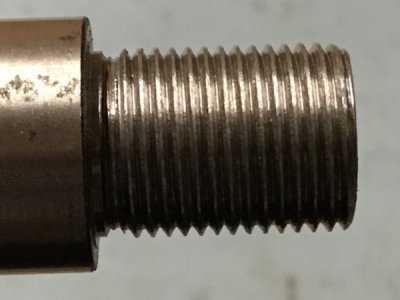

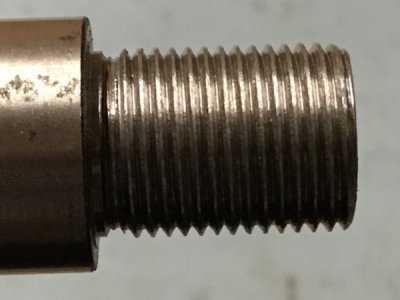

I hate to bust your bubble, the cross feed screw I have here in my hands has 12 teeth and a OD of .687".

My old model C cross feed screw has the OD turned down to about .500" so gear teeth could not be cut on the screw.

May want to check this one more time.

Ken

I hate to bust your bubble, the cross feed screw I have here in my hands has 12 teeth and a OD of .687".

My old model C cross feed screw has the OD turned down to about .500" so gear teeth could not be cut on the screw.

May want to check this one more time.

Ken

OK....Forgive me the the long post to follow but I just wanted to update my original post about the upgrade to a model B from a C. This has been a very long road, especially since I am just starting this hobby and have limited knowledge and limited tooling. The tooling is another issue as I was tooling up before I even had finished getting my mill working.

Anyway, the main issue here was that my SB 9C was fairly well worn. My cousin gave it to me and its a big improvement from my Atlas 618. That said, the Atlas saved my butt a couple of times because its nice to have a second lathe available plus I was missing the change gear needed to thread 24t threads.

FWIW....the main reason I reached the desire to upgrade to a Model B was that my model C apron was flat garbage. The hand wheel to move the carriage literally has about an EIGHT of an inch slop up and another 1/8 down. I'm talking almost 1/4 worn. Its a wonder it worked at all.

So, I found a good used model B apron on Ebay for about 100.00 bucks plus shipping. Good score IMO

Then I tried to braze a bronze bushing to the old cross feed screw.

Anyway, the main issue here was that my SB 9C was fairly well worn. My cousin gave it to me and its a big improvement from my Atlas 618. That said, the Atlas saved my butt a couple of times because its nice to have a second lathe available plus I was missing the change gear needed to thread 24t threads.

FWIW....the main reason I reached the desire to upgrade to a Model B was that my model C apron was flat garbage. The hand wheel to move the carriage literally has about an EIGHT of an inch slop up and another 1/8 down. I'm talking almost 1/4 worn. Its a wonder it worked at all.

So, I found a good used model B apron on Ebay for about 100.00 bucks plus shipping. Good score IMO

Then I tried to braze a bronze bushing to the old cross feed screw.

Last edited:

So...it worked, but not great. That gear on the crossfeed was warped/bent. And it binded on every revolution. So...time for an upgrade to larger dials and I figured I would try to cut an Acme Left hand 7/16" screw. Yes...it would be a challenge. Cut the crossfeed/dial housing and then brazed together.

Last edited: