- Joined

- Nov 24, 2013

- Messages

- 254

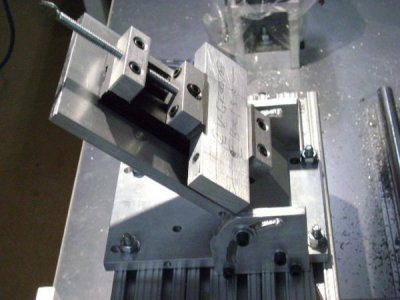

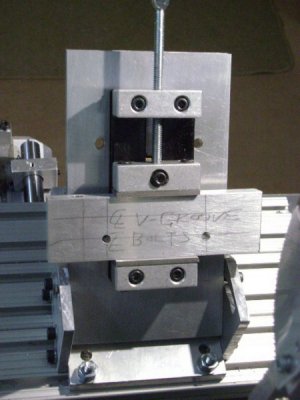

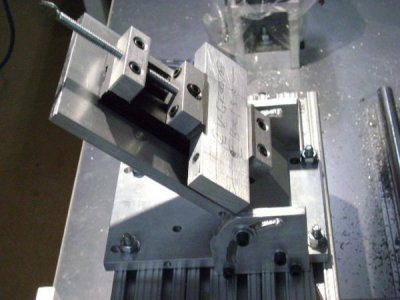

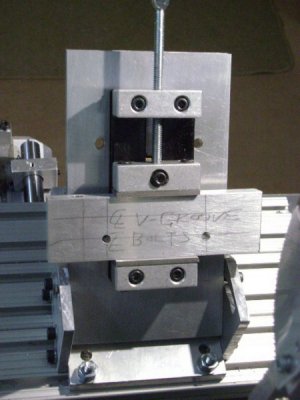

I will try to make a horizontal V Groove on the stock shown in the attached pictures which will be one of the jaws for a homemade vise. I know aluminum is not a good material for a vise jaw but for a hobby use I’m sure it will be ok and it’s also a good exercise.

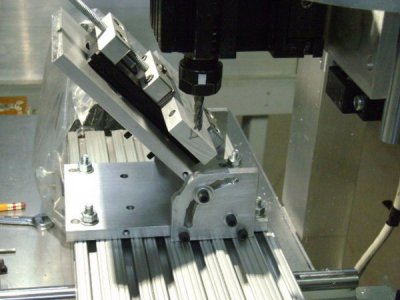

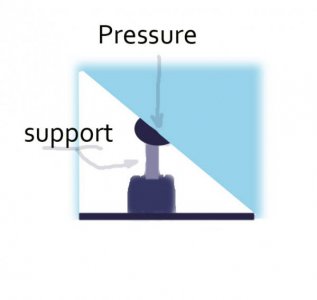

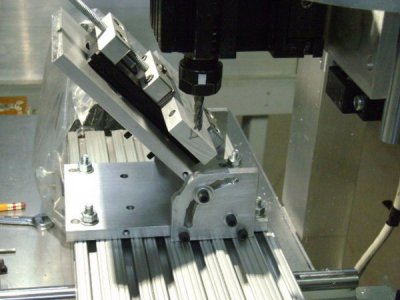

The stock is 0.5” x 1.5” x 5.0” and is attached to a home built Tilt Table set now at 45 degrees. The last picture show the 0.25” OD 4 flute end mill which will be used to do the cut and I will pull the stock against the end mill (I assume this will be a conventional cut).

Is this an acceptable setup?

Nicolas

The stock is 0.5” x 1.5” x 5.0” and is attached to a home built Tilt Table set now at 45 degrees. The last picture show the 0.25” OD 4 flute end mill which will be used to do the cut and I will pull the stock against the end mill (I assume this will be a conventional cut).

Is this an acceptable setup?

Nicolas