- Joined

- Sep 20, 2021

- Messages

- 152

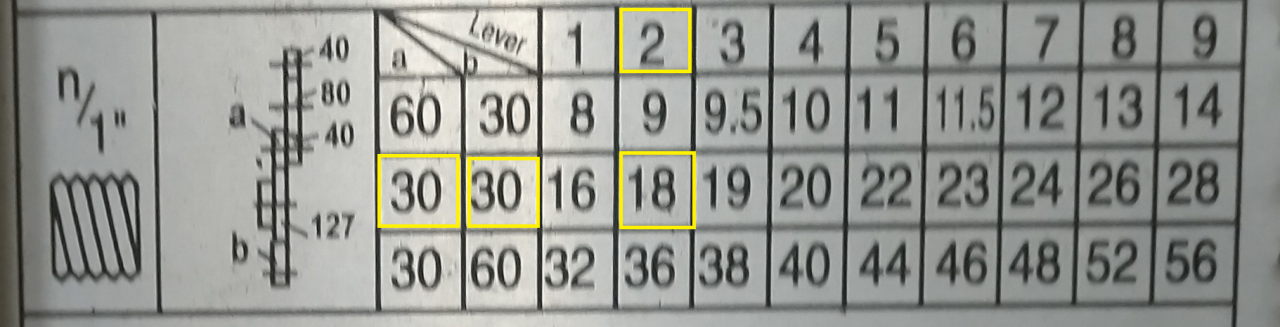

According to the chart on the front of the machine, to achieve 18 tpi I have to configure the machine like this:

a=30

b=30

Lever = 2

I don't think I have to mess with the top 40-80-40 gears - going to leave them alone. I'll start with "a" and make it 30 which will then mate to 127 idler which connects to "b" that I will set to 30 as well. According to the chart - IF I understand it correctly.

That's the initial plan anyway. Thx -

a=30

b=30

Lever = 2

I don't think I have to mess with the top 40-80-40 gears - going to leave them alone. I'll start with "a" and make it 30 which will then mate to 127 idler which connects to "b" that I will set to 30 as well. According to the chart - IF I understand it correctly.

That's the initial plan anyway. Thx -