- Joined

- Apr 28, 2014

- Messages

- 3,590

Need some suggestions for alternate media. What are others using?

I snagged two of them at auction this summer.

They were setup for 'wet' use - not sure what media they were using.

I of course went with the green rust removing media from HF.

(Which by the way they no longer apply a discount to since it has 'Central Machinery' on the label. )

)

Had a small crack in the tub so I sealed that with epoxy and it's holding - so far.

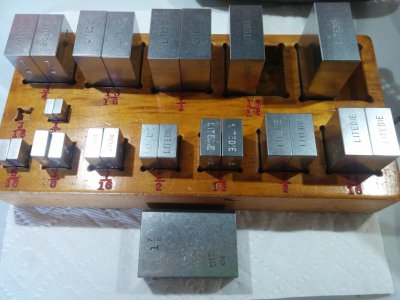

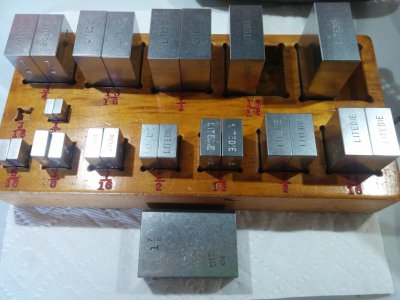

The cool set of gage blocks scored at another auction need corrosion removal so I decided to run them through the tumbler.

Ran them through in groups of three so as not to bang them around too much.

I've got the tumblers in the front of the storage trailer due to the noise factor.

I put the first batch in added a bit of water (possible mistake) and let it run.

Then I fell under the weather and forgot that they were tumbling. A day and half later I remembered.

Well, the 'dust' from the green pyramids turns into a sludge that resembles brick mortar. Quite gunky.

Dumped them, rinsed them. and continued.

I scored two buckets of ceramic media at the auction, I'll have to get some picts today and post them later.

I've run the ceramic in the other tumbler -dry, and it doesn't seem to do much.

Before:

After:

Need to go back over them and brush out the gunk in the stamped numbers.

Need to go back over them and brush out the gunk in the stamped numbers.

As bought:

And there is a controller box setup with a programmable timer and GFCI power.

And there is a controller box setup with a programmable timer and GFCI power.

I snagged two of them at auction this summer.

They were setup for 'wet' use - not sure what media they were using.

I of course went with the green rust removing media from HF.

(Which by the way they no longer apply a discount to since it has 'Central Machinery' on the label.

Had a small crack in the tub so I sealed that with epoxy and it's holding - so far.

The cool set of gage blocks scored at another auction need corrosion removal so I decided to run them through the tumbler.

Ran them through in groups of three so as not to bang them around too much.

I've got the tumblers in the front of the storage trailer due to the noise factor.

I put the first batch in added a bit of water (possible mistake) and let it run.

Then I fell under the weather and forgot that they were tumbling. A day and half later I remembered.

Well, the 'dust' from the green pyramids turns into a sludge that resembles brick mortar. Quite gunky.

Dumped them, rinsed them. and continued.

I scored two buckets of ceramic media at the auction, I'll have to get some picts today and post them later.

I've run the ceramic in the other tumbler -dry, and it doesn't seem to do much.

Before:

After:

Need to go back over them and brush out the gunk in the stamped numbers.

Need to go back over them and brush out the gunk in the stamped numbers.As bought:

And there is a controller box setup with a programmable timer and GFCI power.

And there is a controller box setup with a programmable timer and GFCI power.