-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turn down shaft of tap

- Thread starter BarryMcM

- Start date

- Joined

- Apr 29, 2019

- Messages

- 2,060

With the interupted cuts and what I have to work with, I would chuck the tap in a drill and head over to the bench grinder. Dont over heat it. Don't take off any more metal than you have to, and dont leave a sharp transition up to the original diameter or that is the spot it will break. The other option is a tool post grinder.

- Joined

- Mar 10, 2013

- Messages

- 1,428

use a hand drill in a vise and use your angle grinder. easy and take your time not to heat it up.

Dave

Dave

- Joined

- Sep 28, 2013

- Messages

- 4,308

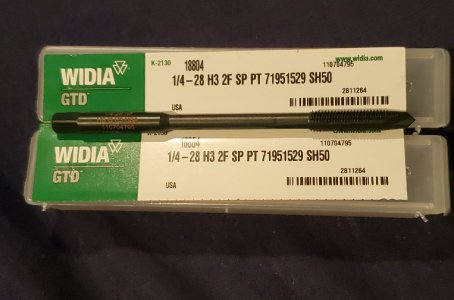

buy a different tap. a) that one is a basic hand tap and you'll have more success with a spiral point (through hole) or spiral flute (blind hole) tap b) thinning the shank weakens the tap which may = broken tap. Presumably the pros have thought about this and accounted for it in their deep hole/ reduced shank taps. Taps are cheap, getting one out of the last hole in a piece you spent hours working on is not

- Joined

- Jan 31, 2016

- Messages

- 11,454

I try to teach my guys , if you're gonna F it up , do it in the beginning of the job . That way you don't waste much time .Taps are cheap, getting one out of the last hole in a piece you spent hours working on is not

Back to the point though , they sell the relieved taps or mount in a whirly jig and grind them on a surface grinder .

- Joined

- Sep 1, 2020

- Messages

- 794

All i can think of is that if in a similar situation, i would likely need the tap right away so ordering a pulley tap wouldn’t be an option i would want. Any of these expeditious means would be cool. Hard turning is really a fantastic thing but not something i have learned enough about to get consistent results. your guys photos and advice are registering with me. Thanks.

- Joined

- Nov 24, 2014

- Messages

- 3,170

I too have done as you described. A wider included angle insert will be stronger for example a square insert with a 90 degree corner will be stronger than the 50 degree included angle on your DCMT insert.

I recommend NOT reducing the shank smaller than the tap drill. The tap can cut crooked more easily if the shank is reduced too small.

View attachment 365836

I see IRWIN brand on the tap shank.

That must be a carbon steel tap (not HSS).