I am still such a nuub when it comes to many shop items even though I have had a Logan lathe for more than three years now. I have a MW 2136 from 1948 which was a family hand-me-down and that machine works great after very simple repairs but that machine does not have a qcgb. Last year, I purchased a l947 Logan 820 that I knew needed some work but I saw it running and lusted after the qcgb. I am slowly taking care of the mechanical items as time allows. So far, new motor, new switches, machined a new motor pulley and new belts. First time running since I got the machine home.

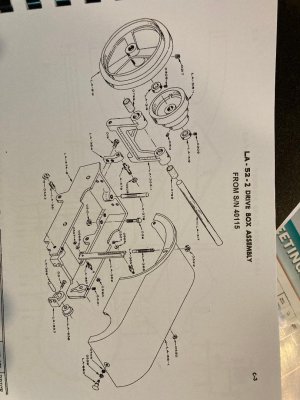

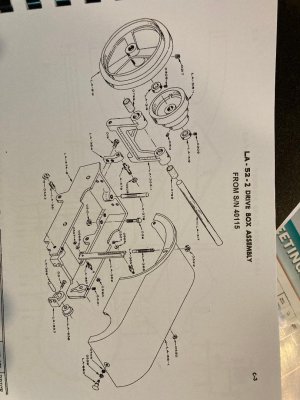

First question. Nuub qualities show up here: noticed a high pitched squeel upon starting the machine, ( I had oiled everything) and it sounded like metal on metal squeel to me. Started looking at the counter shaft and noticed a fair amount of play at the shaft ends so I am assuming I need at a minimum new bushings or possibly a shaft and bushings. My question is about removing the shaft. I dont want to do any damage. The parts diagram below shows the type I have and it looks like removal is just removing the set screws from the shaft collars and the set screw in the cone pulley and then tap/press the parts out. Is that the correct way or am I missing something in the drawings.?

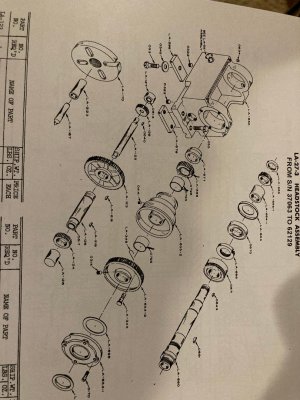

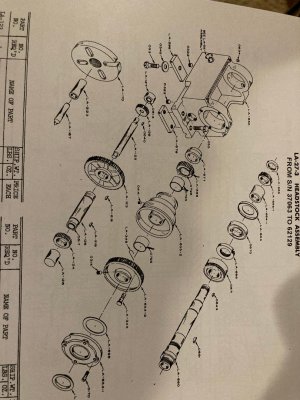

Second question. This seems like it should be obvious but again...nuub! The pull lever that contr ols the back gear seems to operate in the exact opposite manner than my other Logan and from what is written. On the 820 the back gear is engaged when the knob is pushed "in" and direct drive is when the knob is "out". In addition it looks like someone fabricated a rotating "lock" to hold the gear "in" for back gears since it wants to "walk" out without engaging the homemade lock. I assume the eccentric shaft is 180 degrees out of sinc? but I see woodruff keys in the drawings, is that possbile with the keys engaged? I also assume that the whole headstock needs to come out to fix this problem, is that correct? I haven't looked at spindle run out yet so I'm unsure of bearings but if I go into the head-stock, I'm thinking I will likely do the bearings too. Any thoughts?

ols the back gear seems to operate in the exact opposite manner than my other Logan and from what is written. On the 820 the back gear is engaged when the knob is pushed "in" and direct drive is when the knob is "out". In addition it looks like someone fabricated a rotating "lock" to hold the gear "in" for back gears since it wants to "walk" out without engaging the homemade lock. I assume the eccentric shaft is 180 degrees out of sinc? but I see woodruff keys in the drawings, is that possbile with the keys engaged? I also assume that the whole headstock needs to come out to fix this problem, is that correct? I haven't looked at spindle run out yet so I'm unsure of bearings but if I go into the head-stock, I'm thinking I will likely do the bearings too. Any thoughts?

Your thoughts, comments and expertise are welcomed and appreciated.

John from Minnesota

First question. Nuub qualities show up here: noticed a high pitched squeel upon starting the machine, ( I had oiled everything) and it sounded like metal on metal squeel to me. Started looking at the counter shaft and noticed a fair amount of play at the shaft ends so I am assuming I need at a minimum new bushings or possibly a shaft and bushings. My question is about removing the shaft. I dont want to do any damage. The parts diagram below shows the type I have and it looks like removal is just removing the set screws from the shaft collars and the set screw in the cone pulley and then tap/press the parts out. Is that the correct way or am I missing something in the drawings.?

Second question. This seems like it should be obvious but again...nuub! The pull lever that contr

ols the back gear seems to operate in the exact opposite manner than my other Logan and from what is written. On the 820 the back gear is engaged when the knob is pushed "in" and direct drive is when the knob is "out". In addition it looks like someone fabricated a rotating "lock" to hold the gear "in" for back gears since it wants to "walk" out without engaging the homemade lock. I assume the eccentric shaft is 180 degrees out of sinc? but I see woodruff keys in the drawings, is that possbile with the keys engaged? I also assume that the whole headstock needs to come out to fix this problem, is that correct? I haven't looked at spindle run out yet so I'm unsure of bearings but if I go into the head-stock, I'm thinking I will likely do the bearings too. Any thoughts?

ols the back gear seems to operate in the exact opposite manner than my other Logan and from what is written. On the 820 the back gear is engaged when the knob is pushed "in" and direct drive is when the knob is "out". In addition it looks like someone fabricated a rotating "lock" to hold the gear "in" for back gears since it wants to "walk" out without engaging the homemade lock. I assume the eccentric shaft is 180 degrees out of sinc? but I see woodruff keys in the drawings, is that possbile with the keys engaged? I also assume that the whole headstock needs to come out to fix this problem, is that correct? I haven't looked at spindle run out yet so I'm unsure of bearings but if I go into the head-stock, I'm thinking I will likely do the bearings too. Any thoughts?

Your thoughts, comments and expertise are welcomed and appreciated.

John from Minnesota

Last edited: